Table of Contents

مقدمة

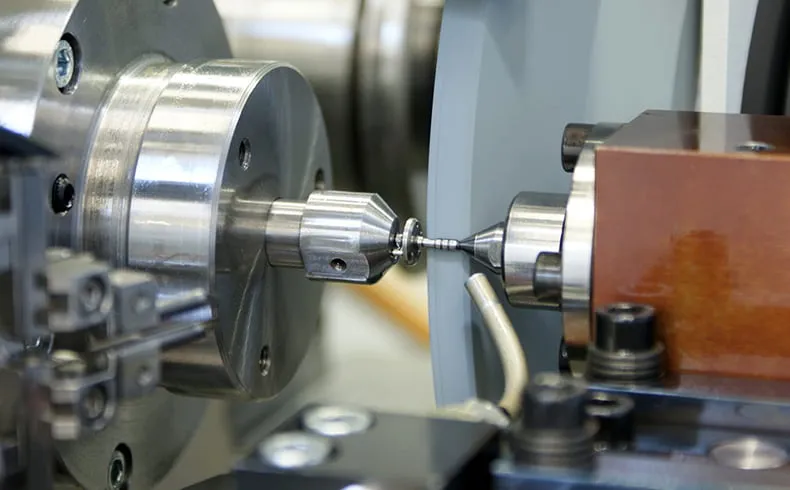

CNC (Computer Numerical Control) machining has emerged as a transformative technology, revolutionizing various industry sectors through its precision and efficiency. As industries evolve to meet the demands of innovation and sustainability, CNC machining advancements play a pivotal role in driving progress.

The Impact of CNC Machining Advancements on Industry Sectors

Aerospace

In the aerospace sector, where every component’s performance can mean the difference between success and failure, CNC machining advancements have made significant strides. From lightweight components that enhance fuel efficiency to intricate parts that withstand extreme conditions, CNC technology ensures aircraft designs are optimized for safety and performance.

Advancements such as hybrid manufacturing combine the benefits of additive manufacturing with traditional CNC processes, enabling the creation of complex geometries previously unattainable. This fusion not only reduces production time but also enhances the durability and reliability of aerospace components.

Healthcare

The healthcare sector is witnessing a paradigm shift thanks to CNC machining advancements. Medical devices, prosthetics, and implants require micron-level accuracy for optimal functionality and patient safety. CNC machining enables the creation of intricate components tailored to individual needs, contributing to personalized medicine.

For instance, titanium spinal implants are meticulously crafted using CNC machines to ensure a perfect fit and maximum effectiveness. The precision achieved through CNC machining is crucial in minimizing surgical complications and improving patient outcomes.

Automotive

The automotive industry relies heavily on CNC machining for the production of intricate engine parts, transmission components, and chassis elements. Advancements in CNC technology have led to optimized manufacturing processes that reduce cycle times and costs while ensuring unparalleled precision.

With the rise of electric vehicles (EVs), lightweight yet robust components are essential for extending range and performance. CNC machining plays a critical role in creating these advanced materials with the necessary accuracy and durability, enabling automakers to innovate and stay ahead of the curve.

Electronics

The electronics sector, characterized by miniaturization and increasing complexity, relies on CNC machining advancements to maintain high standards of precision and quality. From miniature connectors to intricately designed PCB prototypes, CNC machines ensure that even the tiniest components align flawlessly, minimizing signal interference and maximizing performance.

Furthermore, CNC machining enables the production of intricate molds and dies used in electronics manufacturing, accelerating the development of cutting-edge devices. The ability to create precise, high-quality parts is crucial for maintaining the integrity and functionality of electronic systems.

Energy

As the energy landscape evolves towards more sustainable solutions, CNC machining advancements play a vital role in optimizing components that harness renewable resources efficiently. From turbine blades used in wind power generation to precision-machined components in oil and gas exploration, CNC machines ensure that these critical elements are manufactured with utmost accuracy and reliability.

The durability and performance integrity of energy-related components are paramount for efficient resource utilization and environmental sustainability. CNC machining enables the production of robust parts capable of operating under harsh conditions while maintaining optimal performance.

Defence

In the defence sector, where precision is a matter of national security, CNC machining advancements have proven indispensable. From aerospace components in military aircraft to intricate parts in missile systems, CNC machines ensure that critical defence systems operate flawlessly.

Advancements such as simultaneous multi-axis machining enable the creation of complex geometries that were once unattainable. This level of precision is not only crucial for functionality but also ensures operational readiness and reliability in high-stakes scenarios.

الخاتمة

The influence of CNC machining advancements reverberates across various industry sectors, each benefiting from enhanced precision, efficiency, and innovation. As CNC technology continues to evolve, it empowers manufacturers to push boundaries, crafting solutions that were once considered unfeasible. The fusion of CNC machining with emerging technologies like AI and IoT further enhances operational capabilities, ushering in an era where predictive maintenance, real-time monitoring, and data-driven insights become the norm.

As we stand on the cusp of a new industrial revolution, the impact of CNC machining advancements is poised to reshape industry sectors in ways that were once the realm of imagination. The future promises even greater opportunities for innovation and growth, driven by the relentless pursuit of precision and efficiency through CNC machining.