Introduction

Making silicone molds is a fascinating and versatile process that allows for the creation of intricate and detailed molds used in various industries. To achieve flawless and high-quality molds, it is essential to pay meticulous attention to the mixing and pouring stages. Air bubbles and lumps in the silicone can mar the final mold, affecting the casting process and the quality of the end product. In this comprehensive guide, we will explore some essential tips to ensure proper mixing and pouring of silicone, leading to a smooth and bubble-free mold.

Understanding the Importance of Proper Mixing and Pouring in making silicone molds

Before we delve into the tips, let’s first understand the significance of proper mixing and pouring in making silicone molds. Silicone is a versatile material known for its flexibility, durability, and ability to capture intricate details. However, it is also sensitive to certain factors during the mixing and pouring stages. Controlling air bubbles and lumps is critical to achieve a mold that replicates the desired shape and surface texture accurately.

Tip 1: Choose the Right Silicone

The first step in ensuring a successful in making silicone molds is to select the appropriate silicone material. Different types of silicone have varying viscosities and curing times. Opt for a silicone that suits your specific project and provides ample working time for mixing and pouring.

Tip 2: Prepare the Work Area

A clean and organized work area is essential for successful silicone mixing and pouring. Ensure that all tools, containers, and surfaces are clean and free of dust or debris, which could potentially contaminate the silicone.

Tip 3: Measure Accurately

Precise measurement of the silicone components is crucial to achieve the correct ratio for mixing. Use calibrated measuring tools to ensure accuracy and consistency in the mixture.

Tip 4: Mix Slowly and Thoroughly

To prevent the introduction of air bubbles, mix the silicone components slowly and thoroughly. Avoid vigorous stirring or rapid mixing, as this can agitate the silicone and lead to air entrapment.

Tip 5: Vacuum Degassing

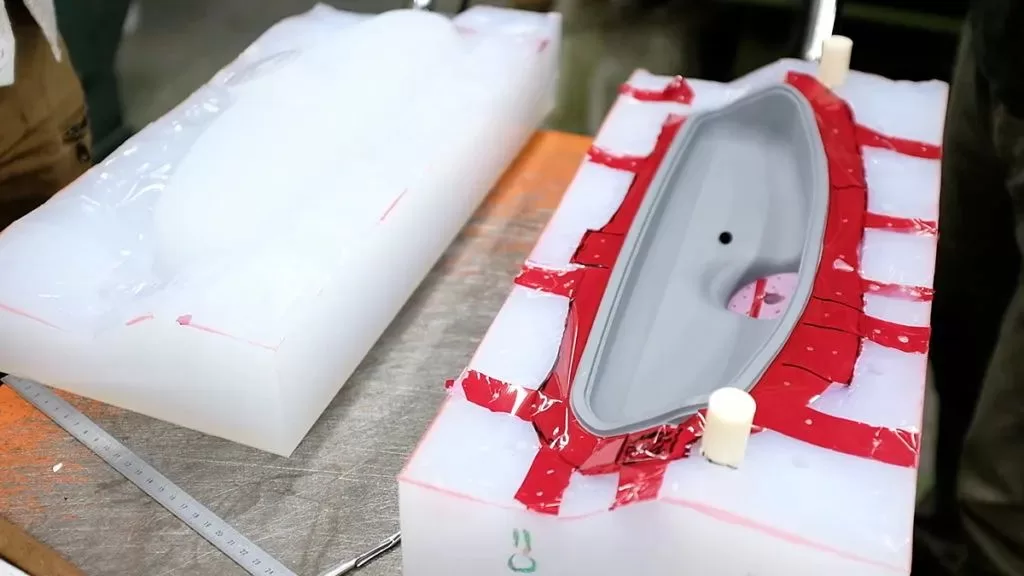

For projects that require the utmost precision and minimal air bubbles, consider utilizing a vacuum degassing chamber. This process removes air bubbles from the silicone mixture, producing a near-perfect mold in making silicone molds.

Tip 6: Tap and Agitate

After pouring the silicone into the mold, gently tap the mold on a solid surface to encourage air bubbles to rise and escape. Additionally, agitate the mold by shaking it lightly to further aid in bubble release.

Tip 7: Use Release Agents

Applying a suitable release agent to the mold’s surface before pouring the silicone in making silicone molds can help minimize surface tension and reduce the likelihood of air bubbles forming.

Tip 8: Avoid Overmixing

While thorough mixing is essential, overmixing can lead to premature curing and the formation of lumps in the silicone mixture. Stick to the recommended mixing time provided by the manufacturer.

Tip 9: Control Pouring Speed

When pouring the silicone into the mold, control the speed of the pour to minimize splashing and air entrapment. A controlled and gradual pour allows the silicone to settle evenly.

Tip 10: Use a Venting System

For complex molds with intricate details, consider incorporating a venting system to allow air to escape during the pouring process. This system helps prevent air bubbles from forming in hard-to-reach areas.

Tip 11: Eliminate Contaminants

Contaminants, such as dust or moisture, can lead to lumps or imperfections in the silicone. Ensure that all tools and materials used are clean and free from any potential contaminants.

Tip 12: Post-Curing Inspection

After the silicone has cured, inspect the mold for any remaining air bubbles or imperfections. For minor imperfections, small touch-ups can be made to achieve a flawless mold.

Conclusion

Achieving a bubble-free and lump-free silicone mold is crucial to obtaining high-quality castings and precise reproductions. By following these essential tips, you can ensure proper mixing and pouring of silicone, leading to successful mold making and the creation of intricate and flawless products across various industries.

In this comprehensive guide, we have explored essential tips for ensuring proper mixing and pouring of silicone when making molds. By implementing these techniques, you can achieve bubble-free and lump-free molds, resulting in superior castings and the production of intricate and high-quality products. If you have any additional questions or need further assistance, please feel free to reach out.”