You Desgin it WE made it

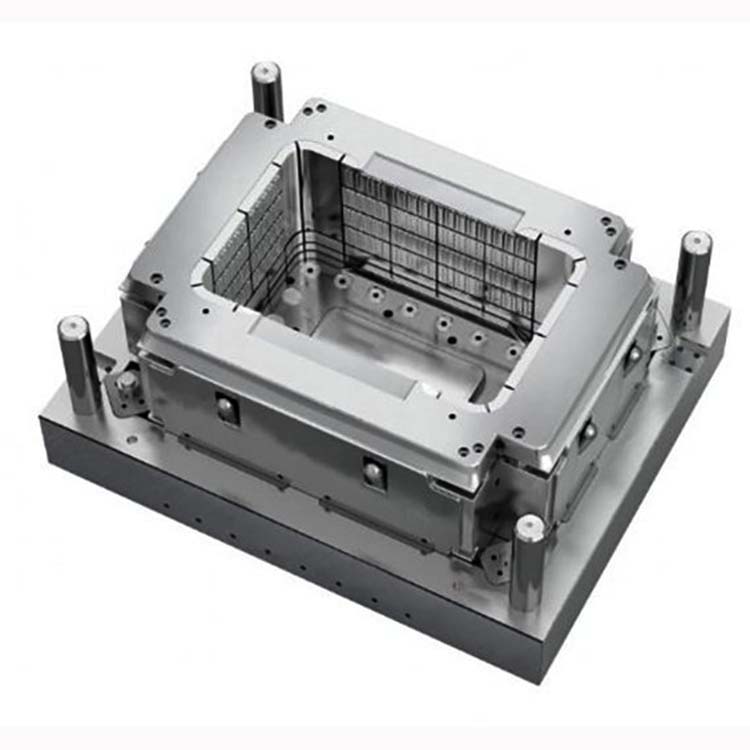

Injection Molding Service

Direct Factory Savings: Save 20% by cutting out the middleman.

Fast Quotes: Get a quote within 12 hours.

Quick Delivery: Get your products in as fast as 3 days.

Why Choose Our Injection Molding Service?

We specialize in providing high-precision injection molding services. Our factory is equipped with advanced injection molding machines ranging from 45 to 1200 tons, capable of processing a wide variety of materials including ABS, PC, PP, PE, POM, PA, and more. Our production line is highly automated, ensuring that every step, from mold design to product delivery, meets the highest quality standards. We also offer two-shot molding and insert molding to meet the needs of complex products.

Sample parts are included with each new tooling order for customer review

No minimum quantity – Injection molds are our specialty

Fast and competitively priced Engineering Changes allow us to react very quickly to design updates and to test multiple concepts

Injection Molding Service Processes

01

Requirement Analysis

Developing a detailed process plan based on customer requirements.

02

Mold Design & Manufacturing

Utilizing advanced CAD/CAM technology to ensure mold precision and durability.

03

Material Preparation & Setup

Selecting the appropriate materials based on product needs and preparing the machines.

04

Injection Molding

Precision molding to ensure product consistency and high quality.

05

Quality Inspection

Multiple quality checks to ensure products meet customer standards.

06

Final Packaging & Delivery

Completing production on time and delivering products safely and quickly.

Meet Our Team

Our success is built on the expertise of our professional team. Our engineers have over 12+ years of experience in injection molding and are capable of tackling even the most complex project challenges. From mold designers to quality control experts, our team is dedicated to providing you with the best solutions. No matter how complex your project is, our team is here to offer professional support.

What Sets Us Apart?

Direct Factory Savings: Save 20% by cutting out the middleman.

Fast Quotes: Get a quote within 12 hours.

Quick Delivery: Get your products in as fast as 3 days.

Typically, 5 to 10 business days, depending on the complexity. We’ll give you a clear timeline when you request a quote.

Yes, we can help refine your design and guide you through the prototyping process to ensure the best results.

We sign NDAs and follow strict protocols to protect your designs and intellectual property.

Prototyping is for testing and refining new designs, while on-demand manufacturing is for producing small to medium batches of parts quickly.

Pricing depends on the project. We require a deposit to start, with the balance due at completion. We accept various payment methods.

Submit your details online or contact us. We’ll send a quote and guide you on ordering. Get a Quote NOW

Trusted by R&D Groups Worldwide

More than1890 companies from 96 countries trust us, and the number is growing.