You Desgin it WE made it

Sheet Metal Fabrication Service

Custom Fabrication Solutions Tailored to Your Specific Needs

Why Choose Our Sheet Metal Fabrication Service?

Our Sheet Metal Fabrication services give you precision, flexibility, and speed, perfect for meeting the needs of many industries. Whether you need custom parts or large production runs, we provide solutions designed just for you. We focus on quality at every step, making sure your parts are delivered on time and meet your exact requirements.

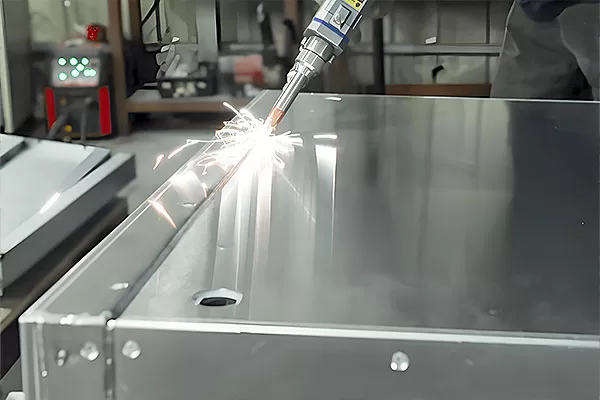

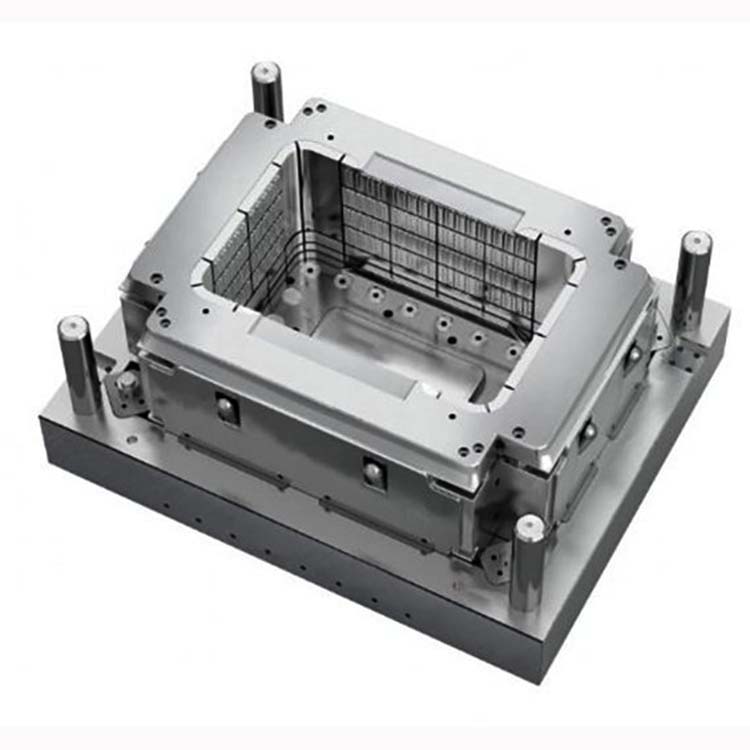

Sheet Metal Fabrication Processes

Our Sheet Metal Fabrication services cover everything from cutting and bending to stamping and welding, ensuring your parts are made with precision and care. We also provide surface finishing options to give your parts the perfect look and extra durability. Whether you need custom parts or larger production runs, our team uses advanced tools and techniques to meet your exact needs. From start to finish, we focus on delivering high-quality, reliable parts on time.

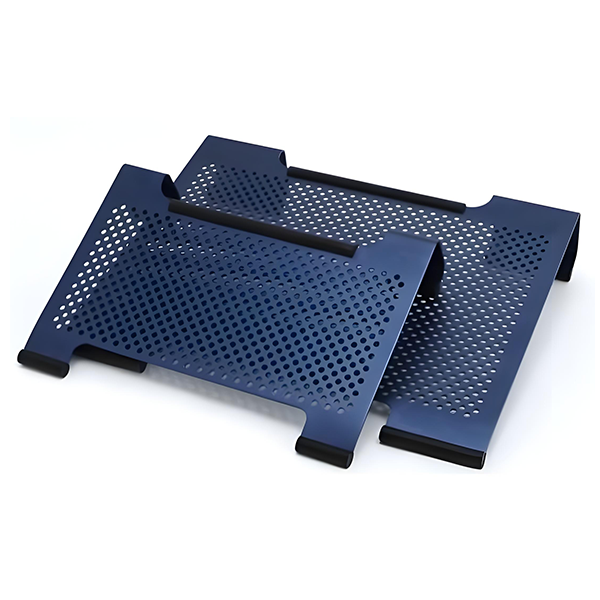

Surface Finshing

In our Sheet Metal Fabrication service, we provide a wide range of surface finishing options, including finishing, painting, and assembly. This helps make your parts look great and protects them from damage. Our team works carefully to ensure every part is finished to your exact needs.

Learn moreMaterial Options for Sheet Metal Fabrication

We offer a wide range of material options, including ABS, PLA, nylon, aluminum, titanium alloy, stainless steel, and resin. Choose the best material for your application to ensure the prototype’s performance and appearance are top-notch.

Characteristics: Lightweight, corrosion-resistant, good conductivity and thermal conductivity, easy to process. Applications: Aerospace, automotive parts, electronics, construction materials.

Characteristics: Excellent corrosion resistance, high strength, high-temperature resistance, easy to clean. Applications: Cutlery, medical instruments, architectural structures, food processing equipment.

Characteristics: Good conductivity and thermal conductivity, corrosion-resistant, easy to weld. Applications: Electrical wires, electrical components, piping, decorative items.

Characteristics: High strength, corrosion-resistant, lightweight, good biocompatibility. Applications: Aerospace, medical implants, chemical equipment.

What Sets Us Apart?

Direct Factory Savings: Save 20% by cutting out the middleman.

Fast Quotes: Get a quote within 12 hours.

Quick Delivery: Get your products in as fast as 3 days.

Typically, 5 to 10 business days, depending on the complexity. We’ll give you a clear timeline when you request a quote.

Yes, we can help refine your design and guide you through the prototyping process to ensure the best results.

We sign NDAs and follow strict protocols to protect your designs and intellectual property.

Prototyping is for testing and refining new designs, while on-demand manufacturing is for producing small to medium batches of parts quickly.

Pricing depends on the project. We require a deposit to start, with the balance due at completion. We accept various payment methods.

Submit your details online or contact us. We’ll send a quote and guide you on ordering. Get a Quote NOW

Medical Devices

Automotive Industry

Consumer Electronics

Education & Training

Sheet Metal Fabrication Service Surface Finishing

We provide various surface finishing techniques, including polishing, electroplating, painting, and anodizing. Whether to enhance the appearance or improve durability, we offer the best finishing solutions for your project.

Trusted by R&D Groups Worldwide

More than1890 companies from 96 countries trust us, and the number is growing.

Our Clients Success Stories

What Our Clients Say

Client’s trust is the key to our success

★★★★★

Being able to get prototypes so fast has really sped up our development process.

Aaron

★★★★★

The quality of the parts we’ve received has always been top-notch. They really pay attention to the details.

Brandon

★★★★★

Their on-demand manufacturing service makes it easy for us to scale production as needed. It’s incredibly convenient.

William

★★★★★

A lot of professional advice to speed up the progress of my project, great!

Smith