Vous l'avez dessiné, nous l'avons fait

Service d'usinage CNC

Économies directes d'usine : Économisez 20% en supprimant les intermédiaires.

Citations rapides : Obtenez un devis dans les 12 heures.

Livraison rapide : Obtenez vos produits dans un délai de 3 jours.

Pourquoi choisir Our CNC Machining Service?

We provide a variety of Precision CNC Machining service that includes CNC Milling, CNC Turning and surface grinding. Whether you’re designing parts that demand high volumes or only running trials with prototypes for low-volume production, our CNC machining services are available to avail you iterative development with quick turnaround and consistency in quality. Both of these processes CNC Turning and CNC milling are designed to achieve specific aims in manufacturing from jigs and fixtures to parts with cylindrical properties, holes, slots and grooves.

Service d'usinage CNC Processus

We offer a variety of CNC machining processes, including milling, turning, drilling, and surface grinding. Each process has its unique advantages and is suited to different stages of product development, ensuring precision, efficiency, and high-quality results.

CNC Milling

CNC milling is a precision machining process that uses computer-controlled rotary cutters to remove material from a workpiece, allowing for the creation of complex shapes and high-accuracy parts.

CNC Turning

CNC turning is a machining process where a computer-controlled lathe rotates the workpiece while cutting tools shape it, ideal for producing precise cylindrical parts with high accuracy.

Grinding Machining

Grinding machining uses abrasive wheels to remove material and achieve a smooth, precise finish, ideal for fine-tuning surfaces and achieving tight tolerances.

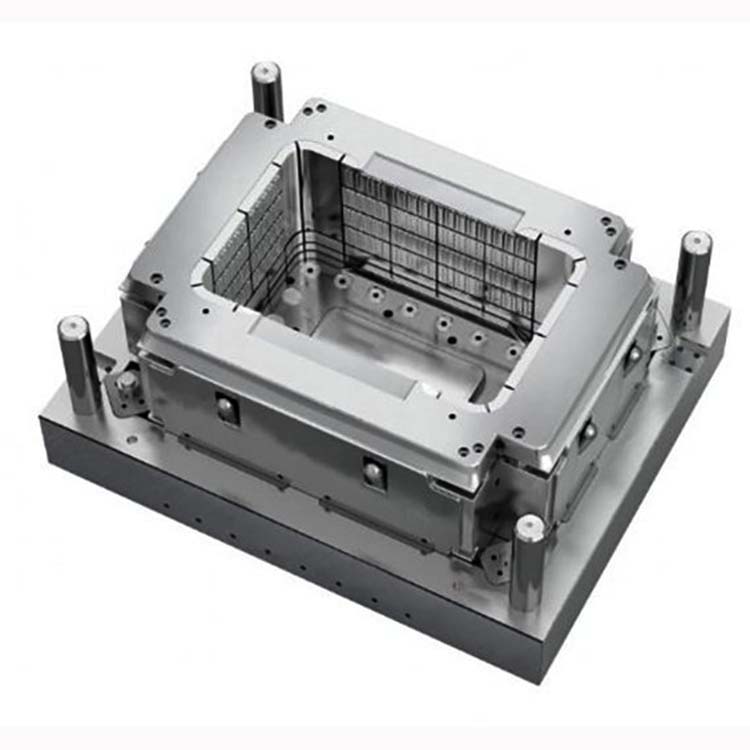

EDM (Electrical Discharge Machining)

EDM (Electrical Discharge Machining) uses electrical sparks to precisely shape hard materials, offering high accuracy and the ability to machine complex geometries that are difficult to achieve with traditional methods.

Réalisez votre projet en 4 étapes

01

Télécharger un fichier CAO

Téléchargez facilement votre fichier CAO 3D.

02

Devis et analyse de la conception

Recevoir un devis détaillé et un retour d'information.

03

Commande confirmée

Confirmez votre commande et lancez la production.

04

Les pièces sont expédiées

Recevez vos pièces détachées à domicile.

Notre solution sectorielle

Des services de prototypage sur mesure pour répondre aux défis et aux besoins uniques de chaque secteur d'activité

Dispositifs médicaux

Industrie automobile

Électronique grand public

Éducation et formation

Confiance de la part de Groupes de R&D Dans le monde entier

Plus de 1890 entreprises de 96 pays nous font confiance, et ce nombre ne cesse de croître.

Qu'est-ce qui nous distingue ?

Économies directes d'usine : Économisez 20% en supprimant les intermédiaires.

Citations rapides : Obtenez un devis dans les 12 heures.

Livraison rapide : Obtenez vos produits dans un délai de 3 jours.

En général, 5 à 10 jours ouvrables, en fonction de la complexité. Nous vous donnerons un calendrier précis lorsque vous demanderez un devis.

Oui, nous pouvons vous aider à affiner votre conception et vous guider tout au long du processus de prototypage afin d'obtenir les meilleurs résultats.

Nous signons des accords de confidentialité et suivons des protocoles stricts pour protéger vos dessins et votre propriété intellectuelle.

Le prototypage permet de tester et d'affiner de nouvelles conceptions, tandis que la fabrication à la demande permet de produire rapidement des lots de pièces de petite ou moyenne taille.

Le prix dépend du projet. Nous demandons un acompte pour commencer, le solde étant dû à l'achèvement du projet. Nous acceptons différents modes de paiement.

Soumettez vos coordonnées en ligne ou contactez-nous. Nous vous enverrons un devis et vous guiderons pour la commande. Obtenir un devis MAINTENANT

Service d'usinage CNC Matériaux

Nous proposons un large éventail de matériaux, notamment l'ABS, le PLA, le nylon, l'aluminium, l'alliage de titane, l'acier inoxydable et la résine. Choisissez le matériau le mieux adapté à votre application pour garantir que les performances et l'aspect du prototype sont de premier ordre.

Plastique

Voici les matières plastiques les plus courantes que nous utilisons. Bien entendu, nous pouvons également traiter d'autres matériaux que vous nous indiquez.

Caractéristiques : Excellente résistance aux chocs, bonne résistance à la chaleur, performance à basse température, facile à traiter, surface lisse. Applications : Intérieurs d'automobiles, boîtiers d'appareils électroménagers, jouets, boîtiers de produits électroniques.

Caractéristiques : Biodégradable, respectueux de l'environnement, point de fusion bas, facile à traiter. Applications : Impression 3D, matériaux d'emballage, implants médicaux.

Caractéristiques : Haute résistance, résistance à l'usure, résistance chimique, bonne résistance à la fatigue. Applications : Engrenages industriels, roulements, pièces mécaniques, textiles.

Caractéristiques : Grande transparence, forte résistance aux chocs, résistance aux températures élevées, bonne isolation électrique. Applications : Ecrans transparents, protections de sécurité, disques optiques, composants électroniques.

Caractéristiques : Haute résistance chimique, faible absorption d'humidité, bonne résistance aux chocs, légèreté. Applications : Matériaux d'emballage, sacs en plastique, conteneurs, tuyaux.

Métal

Voici les matériaux métalliques les plus courants que nous utilisons. Bien entendu, nous pouvons également traiter d'autres matériaux que vous nous indiquez.

Caractéristiques : Léger, résistant à la corrosion, bonne conductivité et conductivité thermique, facile à traiter. Applications : Aérospatiale, pièces automobiles, électronique, matériaux de construction.

Caractéristiques : Excellente résistance à la corrosion, grande solidité, résistance aux températures élevées, facile à nettoyer. Applications : Coutellerie, instruments médicaux, structures architecturales, équipements de transformation des aliments.

Caractéristiques : Bonne conductivité et conductivité thermique, résistant à la corrosion, facile à souder. Applications : Fils électriques, composants électriques, tuyauterie, articles de décoration.

Caractéristiques : Haute résistance, résistant à la corrosion, léger, bonne biocompatibilité. Applications : Aérospatiale, implants médicaux, équipements chimiques.

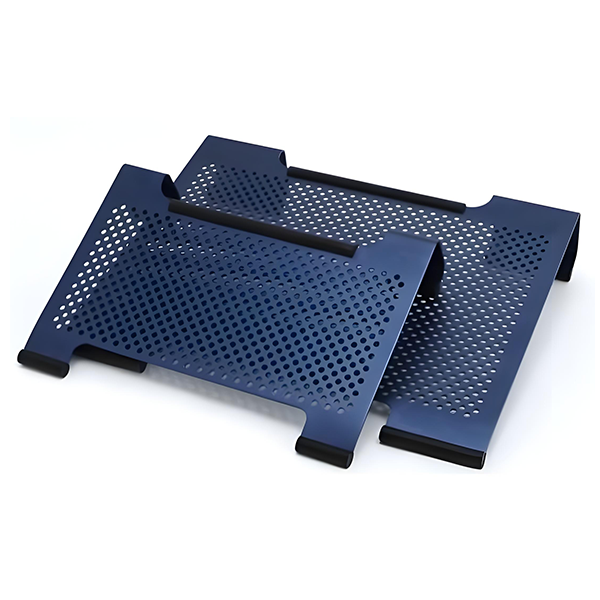

Service d'usinage CNC Finition de surface

Nous proposons diverses techniques de finition de surface, notamment le polissage, la galvanoplastie, la peinture et l'anodisation. Que ce soit pour améliorer l'apparence ou la durabilité, nous offrons les meilleures solutions de finition.

Ce que notre Ce que disent les clients

La confiance du client est la clé de notre succès

★★★★★

Le fait de pouvoir obtenir des prototypes aussi rapidement a vraiment accéléré notre processus de développement.

Aaron

★★★★★

La qualité des pièces que nous avons reçues a toujours été excellente. Ils font vraiment attention aux détails.

Brandon

★★★★★

Leur service de fabrication à la demande nous permet d'augmenter facilement la production en fonction des besoins. C'est incroyablement pratique.

William

★★★★★

Beaucoup de conseils professionnels pour accélérer l'avancement de mon projet, génial !

Smith