Vous l'avez dessiné, nous l'avons fait

low-volume manufacturing service

Accelerate your product launch with our expert low-volume manufacturing service. Perfect for prototyping, market testing, and small batch production.

Économies directes d'usine : Économisez 20% en supprimant les intermédiaires.

Citations rapides : Obtenez un devis dans les 12 heures.

Livraison rapide : Obtenez vos produits dans un délai de 3 jours.

Why Choose Our Low-Volume Manufacturing Service?

Choosing the right manufacturing partner for low-volume manufacturing can be a game-changer. Our team ensures top-notch quality, flexibility, and cost-efficiency, allowing you to focus on bringing your innovative products to market swiftly and confidently.

Our Low-Volume Manufacturing Service Processes

Low-volume manufacturing Service, we provide comprehensive solutions tailored to your needs. Include: 3D Sprinting, Usinage CNC, Mold Making, Injection Molding, Fabrication de tôles, Rapid Casting, Coulée sous vide ect.

Coulée sous vide

Vacuum casting uses silicone molds for cost-effective, quick small-batch production, offering a competitive edge over CNC machining and injection molding.

En savoir plus

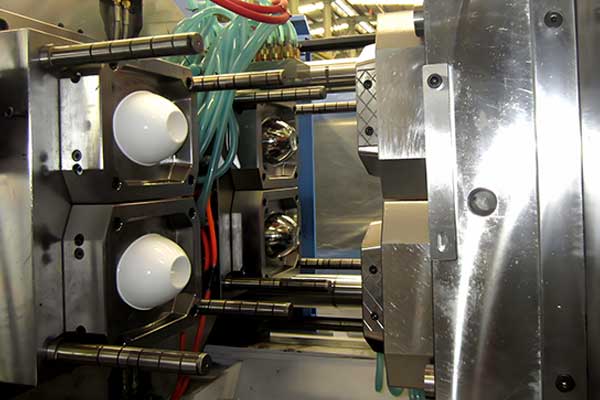

Moulage par injection

Injection molding is a manufacturing process that produces high-quality, precise parts by injecting molten material into a mold, ideal for mass production.

En savoir plus

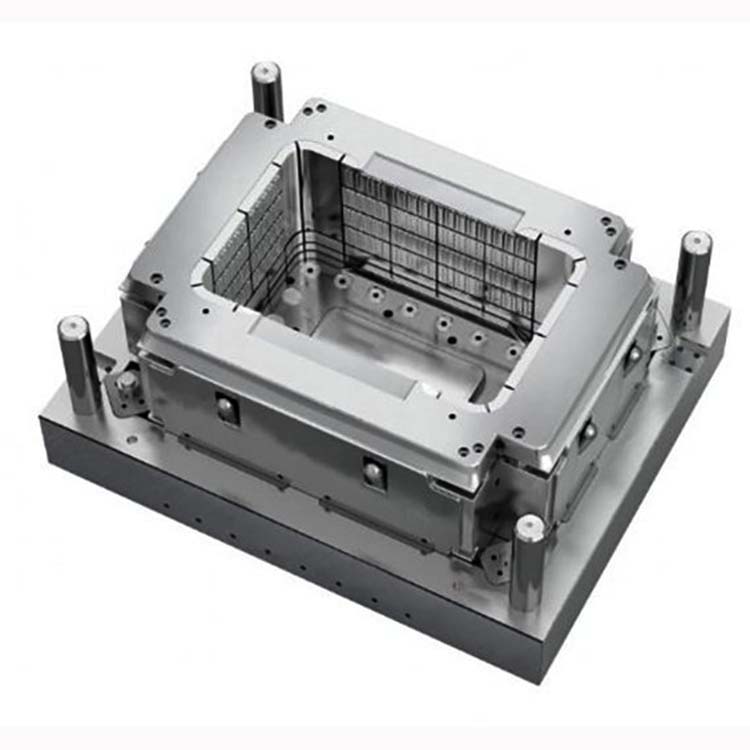

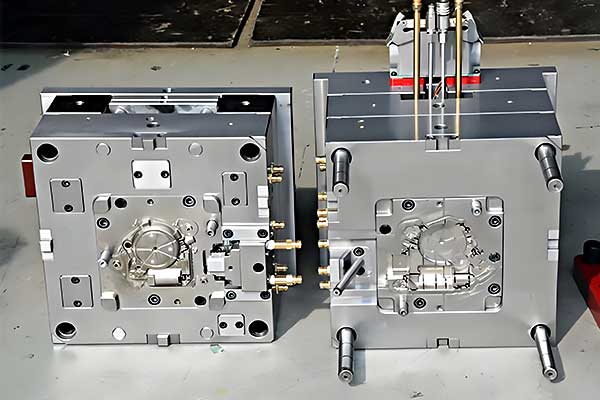

Mold Making

Mold making involves creating precise molds for manufacturing, essential for producing consistent, high-quality parts in various materials.

En savoir plus

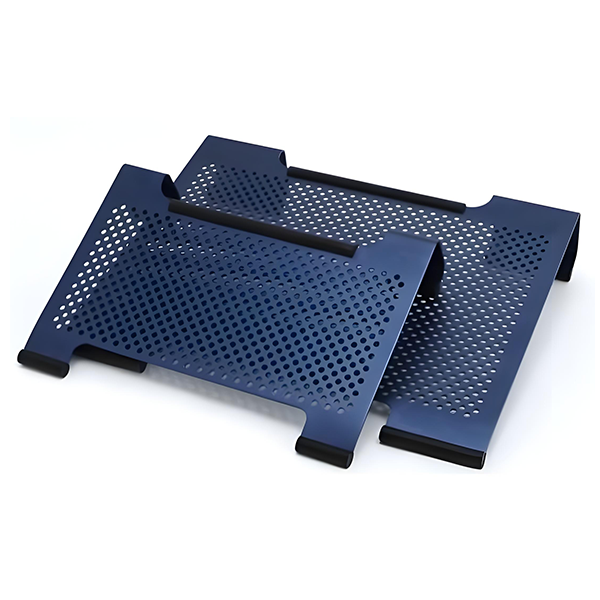

Laser Cutting

Laser cutting uses a focused laser beam to precisely cut materials, offering high accuracy and clean edges for various applications.

get quote

Casting

Casting is a manufacturing process where liquid material is poured into a mold and allowed to solidify, forming precise, durable parts for a variety of applications.

get quote

Contrôle de la qualité

Quality control ensures that products meet specific standards and requirements through systematic inspection, testing, and verification, guaranteeing consistency and reliability in manufacturing.

En savoir plusChoosing the Right Processes

Consider the following chart when deciding which Low-Volume Manufacturing Service is best for your project.

| Process Type | Cost | Production Capacity | Product Precision | Production Efficiency | Per Piece Price |

|---|---|---|---|---|---|

| Coulée sous vide | Medium | Low to Medium | High | Medium | High |

| Moulage par injection | High | High | High | High | High |

| Mold Making | High | Medium | High | Low | Mid |

| Laser Cutting | Low to Medium | Medium to High | High | High | Low |

| Casting | Medium | Medium to High | Medium to High | Medium | High |

Nos solutions sectorielles of Low-Volume Manufacturing Service

Tailored Low-Volume Manufacturing Service for Every Industry’s Unique Challenges and Needs

Dispositifs médicaux

Industrie automobile

Électronique grand public

Éducation et formation

Confiance de la part de Groupes de R&D Dans le monde entier

Plus de 1890 entreprises de 96 pays nous font confiance, et ce nombre ne cesse de croître.

What Sets Us Apart?

Économies directes d'usine : Économisez 20% en supprimant les intermédiaires.

Citations rapides : Obtenez un devis dans les 12 heures.

Livraison rapide : Obtenez vos produits dans un délai de 3 jours.

Typically, 5 to 10 business days, depending on the complexity. We’ll give you a clear timeline when you request a quote.

Yes, we can help refine your design and guide you through the prototyping process to ensure the best results.

We sign NDAs and follow strict protocols to protect your designs and intellectual property.

Prototyping is for testing and refining new designs, while on-demand manufacturing is for producing small to medium batches of parts quickly.

Pricing depends on the project. We require a deposit to start, with the balance due at completion. We accept various payment methods.

Submit your details online or contact us. We’ll send a quote and guide you on ordering. Get a Quote NOW

Service de fabrication à faible volume Materials

We offer a wide range of material options, including ABS, PLA, nylon, aluminum, titanium alloy, stainless steel, and resin. Choose the best material for your application to ensure the prototype’s performance and appearance are top-notch.

Plastic

Here are the common plastic materials we use. Of course, we can also process other materials you specify.

Characteristics: Excellent impact resistance, good heat resistance, low-temperature performance, easy to process, smooth surface. Applications: Automotive interiors, appliance housings, toys, electronic product casings.

Characteristics: Biodegradable, environmentally friendly, low melting point, easy to process. Applications: 3D printing, packaging materials, medical implants.

Characteristics: High strength, wear resistance, chemical resistance, good fatigue resistance. Applications: Industrial gears, bearings, mechanical parts, textiles.

Characteristics: High transparency, strong impact resistance, high-temperature resistance, good electrical insulation. Applications: Transparent face shields, safety guards, optical discs, electronic components.

Characteristics: High chemical resistance, low moisture absorption, good impact resistance, lightweight. Applications: Packaging materials, plastic bags, containers, pipes.

Metal

Here are the common metal materials we use. Of course, we can also process other materials you specify.

Characteristics: Lightweight, corrosion-resistant, good conductivity and thermal conductivity, easy to process. Applications: Aerospace, automotive parts, electronics, construction materials.

Characteristics: Excellent corrosion resistance, high strength, high-temperature resistance, easy to clean. Applications: Cutlery, medical instruments, architectural structures, food processing equipment.

Characteristics: Good conductivity and thermal conductivity, corrosion-resistant, easy to weld. Applications: Electrical wires, electrical components, piping, decorative items.

Characteristics: High strength, corrosion-resistant, lightweight, good biocompatibility. Applications: Aerospace, medical implants, chemical equipment.

Service de fabrication à faible volume Surface Finishing

We provide various surface finishing techniques, including polishing, electroplating, painting, and anodizing. Whether to enhance the appearance or improve durability, we offer the best finishing solutions.

Nos clients Histoires de réussite

Ce que notre Ce que disent les clients

La confiance du client est la clé de notre succès

★★★★★

Le fait de pouvoir obtenir des prototypes aussi rapidement a vraiment accéléré notre processus de développement.

Aaron

★★★★★

La qualité des pièces que nous avons reçues a toujours été excellente. Ils font vraiment attention aux détails.

Brandon

★★★★★

Their on-demand manufacturing service makes it easy for us to scale production as needed. It’s incredibly convenient.

William

★★★★★

Beaucoup de conseils professionnels pour accélérer l'avancement de mon projet, génial !

Smith