説明

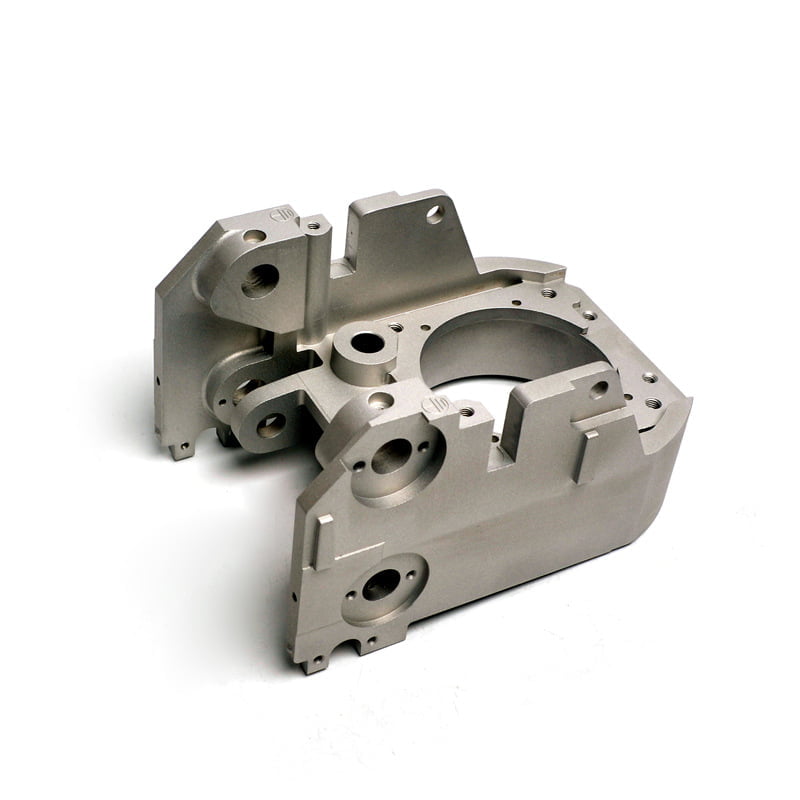

に関しては CNC product prototyping, the use of aluminium alloy holds immense value, especially in the realm of automotive parts. The versatility and exceptional properties of aluminium alloy make it an ideal material choice for creating precise and high-quality prototypes.

の世界では CNC prototype robot parts, the combination of advanced technology and customizability takes center stage. CNC machining allows for the precise fabrication of intricate parts, tailored to the specific requirements of robotic systems. This ensures optimal performance, functionality, and compatibility with the overall design.

One of the key processes involved in creating CNC prototypes for robot parts is oxidation sandblasting. This surface treatment technique not only enhances the visual appeal of the parts but also provides important functional benefits. By creating a layer of oxide on the surface, oxidation sandblasting improves the durability, corrosion resistance, and overall lifespan of the robot parts.

In summary, the utilization of CNC technology for prototyping aluminium alloy automotive parts そして robot parts allows for the development of cutting-edge, customized components. The combination of precision machining and surface treatments like oxidation sandblasting ensures that the final products meet the highest standards of quality, performance, and aesthetics. As the field of robotics continues to advance, CNC product prototyping remains an essential process for creating innovative and efficient robotic systems.

[forminator_form id=”9921″]

レビュー

レビューはまだありません。