You Desgin it WE made it

Topkwaliteit Snelle prototyping Oplossing

Directe fabrieksbesparingen: Bespaar 20% door de tussenpersoon weg te laten.

Snelle citaten: Ontvang binnen 12 uur een offerte.

Snelle levering: Ontvang je producten al binnen 3 dagen.

Onze productieservice

Van snelle prototyping tot de productie van kleine aantallen, wij bieden uitgebreide oplossingen op maat van uw behoeften. Omvatten: Prototypeproductie, 3D-sprinten, CNC-verspaning, mallen maken, spuitgieten, plaatbewerking, vacuümgieten enz.

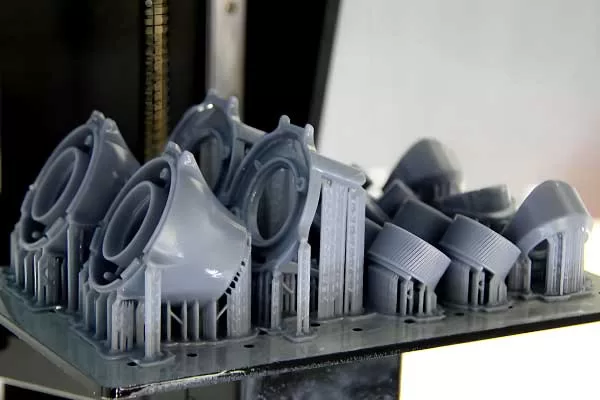

3D afdrukken

FDM, SLA en SLS 3D printservices voor efficiënte en kosteneffectieve rapid prototyping.

Meer informatie

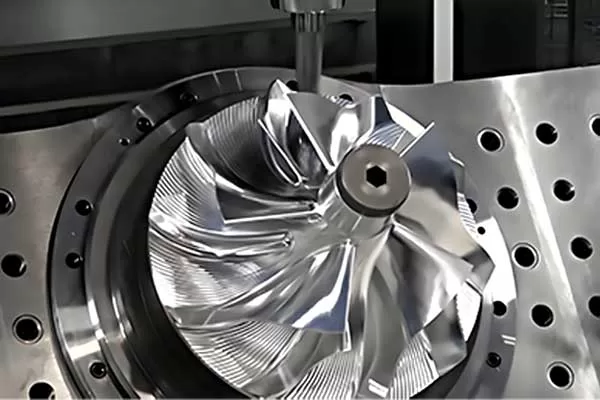

CNC-bewerking

Precisie CNC-bewerking van metalen en kunststof onderdelen om resultaten van hoge kwaliteit te garanderen. Geschikt voor snelle prototyping en productie in kleine aantallen

Meer informatie

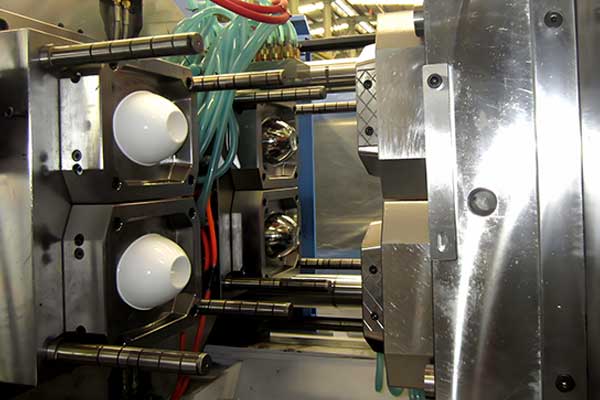

Spuitgieten

Hoogwaardige spuitgietservices voor de productie van kunststof onderdelen in kleine volumes.

Meer informatie

Plaatwerk Fabricage

Plaatbewerking biedt precisie, veelzijdigheid en efficiëntie, waardoor het ideaal is voor hoogwaardige, kosteneffectieve productie en aangepaste prototypes met strikte toleranties.

Meer informatie

Productie van kleine volumes

Productie van kleine aantallen biedt flexibele, kosteneffectieve productie voor kleine batches, waarbij een hoge kwaliteit met snelle levertijden wordt gegarandeerd. Ideaal voor prototypes en producten met een beperkte oplage.

Meer informatie

Oppervlakteafwerking

Een uitgebreide reeks diensten voor oppervlakteafwerking, waaronder afwerken, verven en assemblage.

Meer informatieLaat je ontwerp realiseren in 4 Stappen

01

CAD-bestand uploaden

Eenvoudig uw 3D CAD-bestand uploaden.

02

Offerte & ontwerpanalyse

Ontvang een gedetailleerde offerte en feedback.

03

Bestelling bevestigd

Bevestig je bestelling en start de productie.

04

Onderdelen worden verzonden

Krijg je onderdelen thuisgestuurd.

Vertrouwd door R&D-groepen Wereldwijd

Meer dan1890 bedrijven uit 96 landen vertrouwen op ons en dat aantal groeit nog steeds.

Uw project starten met precisie en snelheid!

Onze brancheoplossing

Prototyping-services op maat voor de unieke uitdagingen en behoeften van elke bedrijfstak

Medische apparaten

Auto-industrie

Consumentenelektronica

Onderwijs & opleiding

Onze klanten Succesverhalen

Onze faciliteiten

Bij QDJ-PROTOTYPE gebruiken we geavanceerde apparatuur om hoogwaardige, nauwkeurige producten te garanderen. Onze machines omvatten CNC-bewerkingscentra, 3D-printers, lasersnijders en testgereedschap van vertrouwde merken zoals Mazak, Haas en TRUMPF. Met een strenge tolerantiecontrole en zorgvuldige inspectie leveren we nauwkeurige prototypes en onderdelen die voldoen aan uw behoeften.

12+

Aantal jaren ervaring

40+

Teamleden

3500+

Project Voltooid

98%

Tevreden klant

Over ons

Wij zijn een leverancier van snelle prototyping- en low-volume productiediensten met 12 jaar ervaring. In China hebben we betrouwbare en stabiele partnerschappen opgebouwd met meer dan 500 kwaliteitsfabrieken via strenge normen voor leveranciersbeheer. Onze ultramoderne faciliteiten en ons deskundige team garanderen precisie, efficiëntie en kwaliteit in elk project voor onze wereldwijde klanten.

Wat onze Klanten zeggen

Het vertrouwen van de klant is de sleutel tot ons succes

★★★★★

Het feit dat we zo snel prototypes kunnen krijgen, heeft ons ontwikkelingsproces echt versneld.

Aaron

★★★★★

De kwaliteit van de onderdelen die we hebben ontvangen is altijd top geweest. Ze letten echt op de details.

Brandon

★★★★★

Hun on-demand productieservice maakt het ons gemakkelijk om de productie op te schalen als dat nodig is. Het is ongelooflijk handig.

William

★★★★★

Veel professioneel advies om de voortgang van mijn project te versnellen, geweldig!

Smith