You Desgin it WE made it

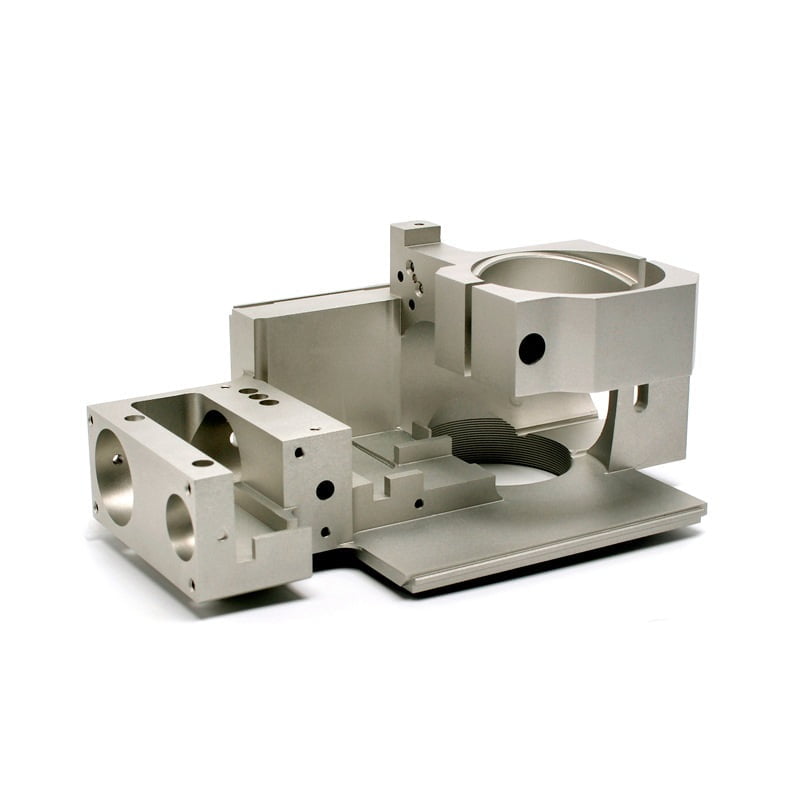

CNC-bewerkingsservice

Directe fabrieksbesparingen: Bespaar 20% door de tussenpersoon weg te laten.

Snelle citaten: Ontvang binnen 12 uur een offerte.

Snelle levering: Ontvang je producten al binnen 3 dagen.

Waarom kiezen Our CNC Machining Service?

We provide a variety of Precision CNC Machining service that includes CNC Milling, CNC Turning and surface grinding. Whether you’re designing parts that demand high volumes or only running trials with prototypes for low-volume production, our CNC machining services are available to avail you iterative development with quick turnaround and consistency in quality. Both of these processes CNC Turning and CNC milling are designed to achieve specific aims in manufacturing from jigs and fixtures to parts with cylindrical properties, holes, slots and grooves.

CNC-bewerkingsservice Processen

We offer a variety of CNC machining processes, including milling, turning, drilling, and surface grinding. Each process has its unique advantages and is suited to different stages of product development, ensuring precision, efficiency, and high-quality results.

CNC Milling

CNC milling is a precision machining process that uses computer-controlled rotary cutters to remove material from a workpiece, allowing for the creation of complex shapes and high-accuracy parts.

CNC Turning

CNC turning is a machining process where a computer-controlled lathe rotates the workpiece while cutting tools shape it, ideal for producing precise cylindrical parts with high accuracy.

Grinding Machining

Grinding machining uses abrasive wheels to remove material and achieve a smooth, precise finish, ideal for fine-tuning surfaces and achieving tight tolerances.

EDM (Electrical Discharge Machining)

EDM (Electrical Discharge Machining) uses electrical sparks to precisely shape hard materials, offering high accuracy and the ability to machine complex geometries that are difficult to achieve with traditional methods.

Laat je ontwerp realiseren in 4 Stappen

01

CAD-bestand uploaden

Eenvoudig uw 3D CAD-bestand uploaden.

02

Offerte & ontwerpanalyse

Ontvang een gedetailleerde offerte en feedback.

03

Bestelling bevestigd

Bevestig je bestelling en start de productie.

04

Onderdelen worden verzonden

Krijg je onderdelen thuisgestuurd.

Onze brancheoplossing

Prototyping-services op maat voor de unieke uitdagingen en behoeften van elke bedrijfstak

Medische apparaten

Auto-industrie

Consumentenelektronica

Onderwijs & opleiding

Vertrouwd door R&D-groepen Wereldwijd

Meer dan1890 bedrijven uit 96 landen vertrouwen op ons en dat aantal groeit nog steeds.

Wat onderscheidt ons?

Directe fabrieksbesparingen: Bespaar 20% door de tussenpersoon weg te laten.

Snelle citaten: Ontvang binnen 12 uur een offerte.

Snelle levering: Ontvang je producten al binnen 3 dagen.

Meestal 5 tot 10 werkdagen, afhankelijk van de complexiteit. We geven je een duidelijke tijdslijn wanneer je een offerte aanvraagt.

Ja, we kunnen helpen bij het verfijnen van je ontwerp en je begeleiden tijdens het prototypingproces om de beste resultaten te garanderen.

We ondertekenen NDA's en volgen strikte protocollen om je ontwerpen en intellectuele eigendom te beschermen.

Prototyping is voor het testen en verfijnen van nieuwe ontwerpen, terwijl productie op aanvraag is voor het snel produceren van kleine tot middelgrote series onderdelen.

De prijs hangt af van het project. We vragen een aanbetaling om te beginnen en het resterende bedrag moet worden betaald bij voltooiing. We accepteren verschillende betalingsmethoden.

Vul je gegevens online in of neem contact met ons op. We sturen je een offerte en begeleiden je bij het bestellen. Vraag NU een offerte aan

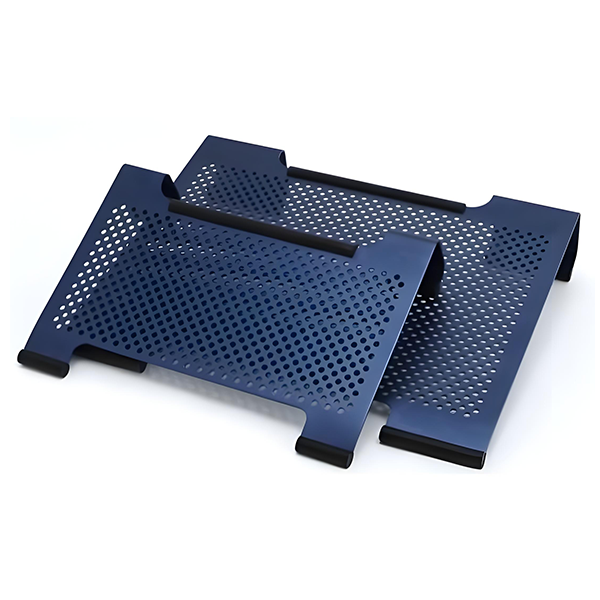

CNC-bewerkingsservice Materialen

We bieden een groot aantal materiaalopties, waaronder ABS, PLA, nylon, aluminium, titaniumlegering, roestvrij staal en hars. Kies het beste materiaal voor jouw toepassing om er zeker van te zijn dat de prestaties en het uiterlijk van het prototype van topklasse zijn.

Kunststof

Dit zijn de gebruikelijke kunststof materialen die we gebruiken. Natuurlijk kunnen we ook andere materialen verwerken die u opgeeft.

Kenmerken: Uitstekende slagvastheid, goede hittebestendigheid, prestaties bij lage temperaturen, gemakkelijk te verwerken, glad oppervlak. Toepassingen: Auto-interieurs, behuizingen van toestellen, speelgoed, behuizingen van elektronische producten.

Kenmerken: Biologisch afbreekbaar, milieuvriendelijk, laag smeltpunt, gemakkelijk te verwerken. Toepassingen: 3D printen, verpakkingsmaterialen, medische implantaten.

Kenmerken: Hoge sterkte, slijtvastheid, chemische weerstand, goede weerstand tegen vermoeidheid. Toepassingen: Industriële tandwielen, lagers, mechanische onderdelen, textiel.

Kenmerken: Hoge transparantie, sterke slagvastheid, weerstand tegen hoge temperaturen, goede elektrische isolatie. Toepassingen: Transparante gelaatsschermen, veiligheidsschermen, optische schijven, elektronische componenten.

Kenmerken: Hoge chemische weerstand, lage vochtabsorptie, goede slagvastheid, lichtgewicht. Toepassingen: Verpakkingsmaterialen, plastic zakken, containers, pijpen.

Metaal

Dit zijn de meest voorkomende metalen materialen die we gebruiken. Natuurlijk kunnen we ook andere materialen verwerken die je opgeeft.

Kenmerken: Lichtgewicht, corrosiebestendig, goede geleidbaarheid en thermische geleidbaarheid, gemakkelijk te verwerken. Toepassingen: Ruimtevaart, auto-onderdelen, elektronica, bouwmaterialen.

Kenmerken: Uitstekende corrosiebestendigheid, hoge sterkte, weerstand tegen hoge temperaturen, gemakkelijk schoon te maken. Toepassingen: Bestek, medische instrumenten, architecturale structuren, voedselverwerkingsapparatuur.

Kenmerken: Goede geleidbaarheid en thermische geleidbaarheid, corrosiebestendig, gemakkelijk te lassen. Toepassingen: Elektrische draden, elektrische componenten, pijpleidingen, decoratieve artikelen.

Kenmerken: Hoge sterkte, corrosiebestendig, lichtgewicht, goede biocompatibiliteit. Toepassingen: Ruimtevaart, medische implantaten, chemische apparatuur.

CNC-bewerkingsservice Oppervlakteafwerking

We provide various surface finishing techniques, including polishing, electroplating, painting, and anodizing. Whether to enhance the appearance or improve durability, we offer the best finishing solution.

Wat onze Klanten zeggen

Het vertrouwen van de klant is de sleutel tot ons succes

★★★★★

Het feit dat we zo snel prototypes kunnen krijgen, heeft ons ontwikkelingsproces echt versneld.

Aaron

★★★★★

De kwaliteit van de onderdelen die we hebben ontvangen is altijd top geweest. Ze letten echt op de details.

Brandon

★★★★★

Hun on-demand productieservice maakt het ons gemakkelijk om de productie op te schalen als dat nodig is. Het is ongelooflijk handig.

William

★★★★★

Veel professioneel advies om de voortgang van mijn project te versnellen, geweldig!

Smith