Вы задумали это, мы сделали это

Mold Making Services

Mold Making Service: Quality Molds for Fast and Reliable Production

Почему стоит выбрать Our Mold Making Services?

Our mold making services are essential for high-volume, precision manufacturing. With our expertise, we deliver molds that are durable, highly accurate, and optimized for efficient production, ensuring cost-effectiveness and consistent quality for your products.

Types of Molds We Specialize In

Our Mold Making Процессы

01

Design

Using advanced CAD/CAM technology to create precise mold designs tailored to your specific needs.

02

Material Selection

Choosing the right materials for the mold, ensuring durability and performance during production.

03

Mold Fabrication

High-precision machining processes to build the mold with exact specifications and tight tolerances.

04

Inspection & Testing

Rigorous quality control checks to ensure the mold meets all design and performance criteria.

05

Trial Runs

Conducting trial production runs to verify the mold’s performance before full-scale production.

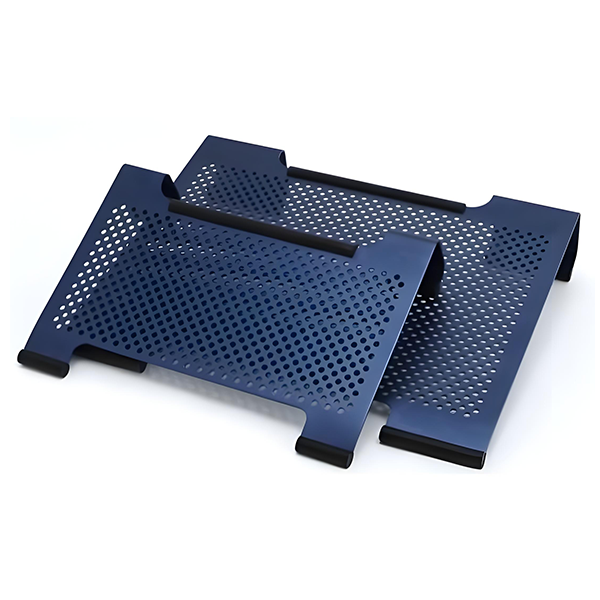

Услуги по изготовлению пресс-форм Материалы

Tool Steel

High-strength, wear-resistant material ideal for long-lasting molds used in high-volume production.

Aluminum

Lightweight and easy to machine, perfect for prototypes and low-volume production molds.

Alloy Steel

Offers a good balance of toughness, machinability, and resistance to wear and tear.

Услуги по изготовлению пресс-форм Отделка поверхности

Мы предлагаем различные технологии отделки поверхностей, включая полировку, гальваническое покрытие, покраску и анодирование. Для улучшения внешнего вида или повышения долговечности мы предлагаем лучшие решения по отделке для Вашего проекта.

Доверяйте Группы по исследованиям и разработкам Весь мир

Нам доверяют более 1890 компаний из 96 стран, и их число постоянно растет.

Наши клиенты Истории успеха

Что наши Клиенты говорят

Доверие клиента - ключ к нашему успеху

★★★★★

Возможность так быстро получать прототипы действительно ускорила наш процесс разработки.

Аарон

★★★★★

Качество деталей, которые мы получали, всегда было на высшем уровне. Они действительно уделяют внимание деталям.

Брэндон

★★★★★

Их услуга производства по требованию позволяет нам легко масштабировать производство по мере необходимости. Это невероятно удобно.

Уильям

★★★★★

Много профессиональных советов, чтобы ускорить продвижение моего проекта, отлично!

Смит