What is Rapid Prototyping?

Rapid prototyping is like having a superpower in product development. It’s the process of quickly bringing ideas to life, allowing designers and engineers to create physical or digital models of products in a flash. Imagine having a magic wand that transforms concepts into tangible prototypes, ready to be tested and refined.

Just like a skilled chef experimenting with new recipes in the kitchen, быстрое прототипирование lets creators mix and match different ingredients—materials and technologies—to cook up innovative solutions to real-world problems. Whether it’s crafting a sleek smartphone casing or designing a cutting-edge medical device, rapid prototyping empowers visionaries to turn imagination into reality at lightning speed.

The Magic Behind Rapid Prototyping

Now, let’s pull back the curtain and explore the enchanting world of rapid prototyping techniques:

1. 3D Printing: Crafting Dreams Layer by Layer

Imagine having a magical printer that can conjure up physical objects out of thin air. That’s the wonder of 3D printing in rapid prototyping. This mesmerizing technique builds prototypes layer by layer, like an artist adding brushstrokes to a canvas, until the final masterpiece emerges.

2. CNC Machining: Sculpting With Precision

Picture a sculptor carving a block of marble with unmatched precision and finesse. That’s the essence of CNC machining in rapid prototyping. This technique uses computer-controlled machines to shape raw materials into intricate prototypes, transforming digital designs into tangible reality.

3. Laser Cutting: Precision Crafting With Laser Beams

Think of a Jedi master wielding a lightsaber, effortlessly slicing through materials with precision and grace. Laser cutting in rapid prototyping harnesses the power of focused laser beams to cut and engrave materials with surgical precision, bringing intricate designs to life with a touch of magic.

4.Vacuum Casting

Vacuum Casting This technique involves creating a silicone mold of the prototype and then using it to create multiple copies of the final product using a vacuum chamber and liquid plastic.

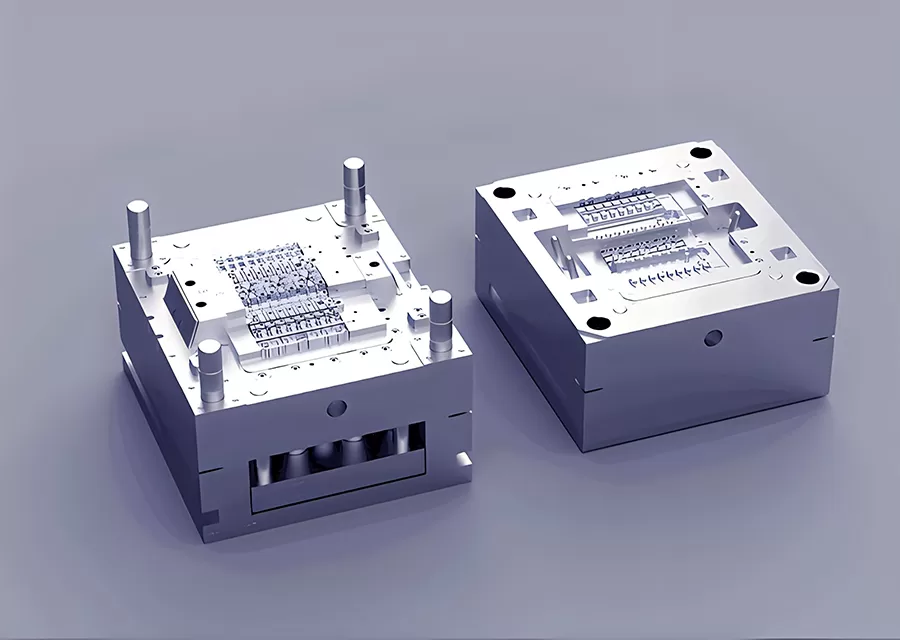

5.Injection Molding

Injection Molding This technique involves injecting molten material into a mold to create the final

product. It’s often used for creating large quantities of plastic parts quickly and efficiently.

6.Sheet Metal Forming

Sheet Metal Forming This technique involves using specialized tools to bend and shape sheet metal into the desired shape. It’s often used for creating parts and components for machines, vehicles, and other products.

Unlocking the Door to Infinite Possibilities

Rapid prototyping isn’t just about creating prototypes; it’s about unlocking the door to infinite possibilities. It’s about daring to dream, innovate, and push the boundaries of what’s possible. Whether you’re a startup striving to disrupt the industry or a seasoned inventor reinventing the wheel, rapid prototyping is your secret weapon in the quest for greatness.

Why Rapid Prototyping Matters

Rapid prototyping isn’t just a buzzword in the world of product development—it’s a game-changer. Here’s why it matters:

1. Speed: From Idea to Prototype in the Blink of an Eye

Time is of the essence in today’s fast-paced world, and rapid prototyping delivers speed like no other. With rapid prototyping, creators can go from concept to prototype in record time, giving them a competitive edge in the race to market.

2. Flexibility: Embracing the Power of Iteration

Flexibility is the name of the game in rapid prototyping. Unlike traditional methods that lock creators into rigid processes, rapid prototyping embraces iteration, allowing designers to refine and improve prototypes on the fly. It’s like having a sculptor’s chisel that can reshape clay with a single stroke, enabling endless possibilities for perfection.

3. Cost-Effectiveness: Maximizing Resources, Minimizing Waste

Money doesn’t grow on trees, and rapid prototyping understands that. By maximizing resources and minimizing waste, rapid prototyping offers a cost-effective solution for bringing ideas to life. It’s like having a magician’s hat full of tricks to stretch every dollar further, ensuring that innovation doesn’t break the bank.

Embracing the Future of Innovation

As we step into the future, rapid prototyping will continue to lead the way in innovation. From breakthroughs in material science to advancements in digital design, the possibilities are limitless. So, embrace the magic of rapid prototyping and embark on a journey of endless creativity and discovery.

The Journey of Rapid Prototyping: From Concept to Creation

Imagine embarking on a journey where every twist and turn leads to new discoveries and innovations. That’s the essence of rapid prototyping—the thrilling adventure of turning ideas into reality. Let’s embark on this exhilarating journey and explore the key stages of rapid prototyping:

1. Ideation: Where Dreams Take Flight

Every great creation starts with a spark of inspiration. In the ideation stage of rapid prototyping, creators unleash their imagination and brainstorm ideas that have the potential to change the world. It’s like embarking on a quest for hidden treasure, where each idea is a precious gem waiting to be unearthed.

During this stage, designers and engineers collaborate closely to define the problem, identify user needs, and set clear objectives for the prototype. It’s a time for blue-sky thinking and daring to dream big, laying the foundation for the journey ahead.

2. Design: From Sketches to Masterpieces

With the vision in mind, it’s time to bring ideas to life through design. Like architects drafting blueprints for towering skyscrapers, designers sketch out the blueprint for the prototype, mapping out every detail with precision and care.

Using cutting-edge design tools like computer-aided design (CAD) software, designers transform concepts into digital renderings, refining and iterating until the design is just right. It’s a process of trial and error, where each iteration brings creators one step closer to perfection.

3. Prototyping: Giving Form to Imagination

Now comes the magic moment—bringing the design to life through prototyping. Like a sculptor molding clay into a work of art, creators choose the appropriate rapid prototyping technique and materials to craft a physical or digital prototype that closely matches the design.

Whether it’s 3D printing, CNC machining, or laser cutting, each technique offers its own unique advantages and challenges. Creators harness the power of technology to breathe life into their creations, transforming pixels into tangible reality.

4. Testing: Putting Prototypes to the Test

With the prototype in hand, it’s time to put it through its paces and see how it fares in the real world. Like scientists conducting experiments in a laboratory, creators conduct usability tests, gather feedback from users, and analyze data to evaluate the prototype’s functionality and user experience.

It’s a time for reflection and refinement, where creators iterate on the design based on user feedback, making tweaks and adjustments until the prototype meets or exceeds expectations. It’s a process of continuous improvement, fueled by a relentless pursuit of excellence.

5. Iteration: Refining and Perfecting

Rapid prototyping is all about iteration—refining and perfecting the design through multiple cycles of testing and refinement. Like a craftsman honing a blade until it’s razor-sharp, creators iterate on the design, making incremental improvements with each cycle.

Whether it’s tweaking the dimensions, adjusting the materials, or fine-tuning the aesthetics, every iteration brings creators closer to their vision of the perfect prototype. It’s a journey of discovery and evolution, where each step forward brings new insights and revelations.

6. Finalization: Ready for the World

After countless hours of hard work and dedication, the prototype is finally ready for its moment in the spotlight. Like a proud parent sending their child off into the world, creators finalize the design and prepare for manufacturing or production.

It’s a time for celebration and anticipation, as creators prepare to unleash their creation upon the world. Whether it’s a groundbreaking new product, a revolutionary piece of technology, or a game-changing innovation, the journey of rapid prototyping is a testament to the power of human creativity and ingenuity.

In the world of rapid prototyping, anything is possible. From humble beginnings to groundbreaking innovations, the journey from concept to creation is a testament to the power of human imagination and perseverance. So, dare to dream, dare to innovate, and dare to push the boundaries of what’s possible. The journey of rapid prototyping awaits, and the possibilities are endless.

Applications of Rapid Prototyping

Now that we’ve explored the journey of rapid prototyping, let’s delve into its wide-ranging applications across various industries. From aerospace to healthcare, rapid prototyping is revolutionizing the way products are designed, tested, and brought to market.

1. Aerospace: Pushing the Boundaries of Flight

In the aerospace industry, precision and innovation are paramount. Rapid prototyping enables engineers to develop and test new aircraft components quickly and efficiently. Whether it’s designing lightweight structures for aircraft interiors or optimizing aerodynamic shapes for wings and fuselages, rapid prototyping accelerates the pace of innovation in aerospace engineering.

2. Healthcare: Transforming Patient Care

Rapid prototyping is also making waves in the healthcare sector, where it’s revolutionizing the design and production of medical devices, implants, and prosthetics. From custom-fitted orthopedic implants to patient-specific surgical guides, rapid prototyping enables healthcare professionals to deliver personalized care with unprecedented precision and accuracy.

3. Automotive: Driving Innovation Forward

In the automotive industry, rapid prototyping is driving innovation forward by facilitating the development of new vehicle designs, components, and technologies. Whether it’s testing aerodynamic concepts in wind tunnels or prototyping complex engine parts, rapid prototyping accelerates the product development process and enables automakers to stay ahead of the competition.

4. Consumer Electronics: Redefining the User Experience

Rapid prototyping is reshaping the consumer electronics landscape by enabling manufacturers to bring new products to market faster and more cost-effectively. Whether it’s prototyping ergonomic designs for smartphones or testing user interfaces for smart home devices, rapid prototyping allows manufacturers to iterate quickly and refine their designs based on real-world feedback.

5. Architecture: Building Tomorrow’s Skylines

In the field of architecture, rapid prototyping is revolutionizing the way buildings are designed and constructed. From conceptual models and scale replicas to functional prototypes of building components, rapid prototyping enables architects to visualize their designs in 3D and identify potential challenges before construction begins. It’s a game-changer for architects, builders, and developers alike.

6. Education: Inspiring the Next Generation of Innovators

Finally, rapid prototyping is transforming education by empowering students to bring their ideas to life in the classroom. From elementary schools to universities, students are using rapid prototyping tools and technologies to design and create projects that address real-world problems and challenges. It’s a hands-on approach to learning that fosters creativity, critical thinking, and innovation.

Embracing the Future

As we’ve seen, rapid prototyping is more than just a tool—it’s a catalyst for innovation, creativity, and progress. Across industries and disciplines, rapid prototyping is unlocking new possibilities and reshaping the way we design, create, and interact with the world around us. So, whether you’re an engineer, designer, or educator, embrace the power of rapid prototyping and dare to turn your dreams into reality.