You Desgin it WE made it

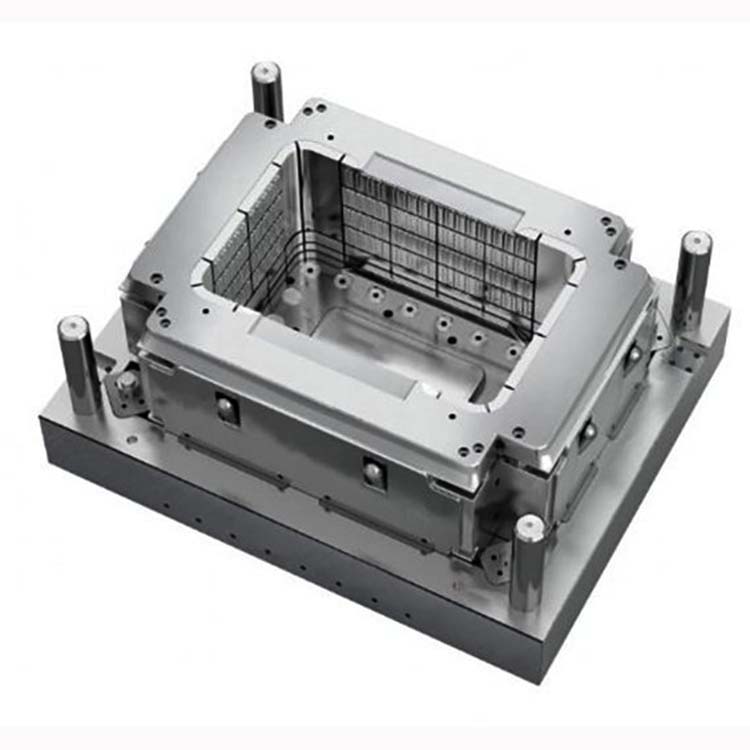

Vacuum Casting Service

Our Vacuum Casting Service delivers high-quality prototypes and small-batch production with precise details and smooth finishes.

Why Choose Our Vacuum Casting Services?

Our Vacuum Casting Service is perfect for making high-quality prototypes and small-batch productions. With our expert team, you’ll get precise and detailed parts that have a smooth surface finish. Plus, our service helps you keep costs down and production times fast. Whether you need a few parts or a small production run, our Vacuum Casting Service gives you the perfect balance of quality, speed, and affordability. Let us help bring your designs to life quickly and efficiently!

Advantages of Vacuum Casting?

Wide Material Selection: Choose from a variety of materials, including polyurethane resins and silicone, suitable for different applications.

High Precision: Produce parts with intricate details and tight tolerances, perfect for functional prototypes and testing.

Low Tooling Costs: Benefit from lower tooling costs compared to traditional molding methods, making it ideal for small runs.

Short Lead Times: Our streamlined process ensures quick turnaround times, helping you bring your products to market faster.

Typically, 5 to 10 business days, depending on the complexity. We’ll give you a clear timeline when you request a quote.

Yes, we can help refine your design and guide you through the prototyping process to ensure the best results.

We sign NDAs and follow strict protocols to protect your designs and intellectual property.

Prototyping is for testing and refining new designs, while on-demand manufacturing is for producing small to medium batches of parts quickly.

Pricing depends on the project. We require a deposit to start, with the balance due at completion. We accept various payment methods.

Submit your details online or contact us. We’ll send a quote and guide you on ordering. Get a Quote NOW

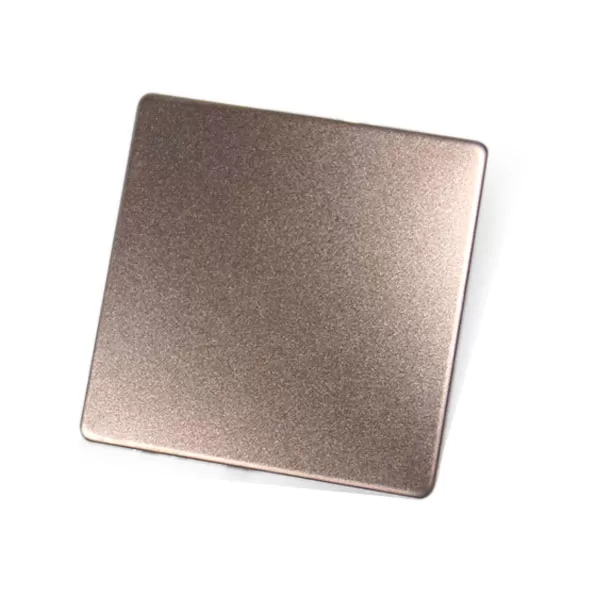

Vacuum Casting Service Materials

We offer a wide range of material options, including ABS, PLA, nylon, aluminum, titanium alloy, stainless steel, and resin. Choose the best material for your application to ensure the prototype’s performance and appearance are top-notch.

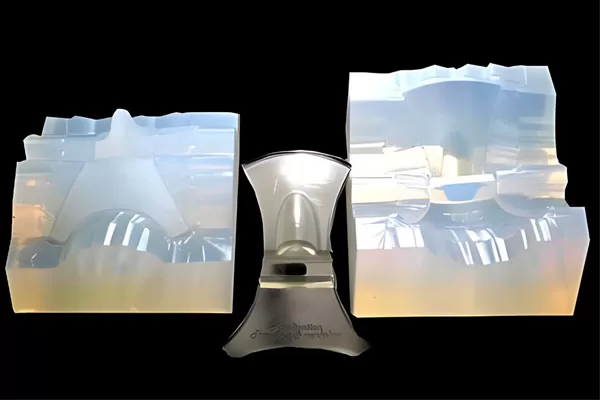

Polyurethane Resins

Offers excellent flexibility, durability, and the ability to simulate a wide range of production plastics.

Silicone

Ideal for creating flexible, high-temperature resistant molds and parts.

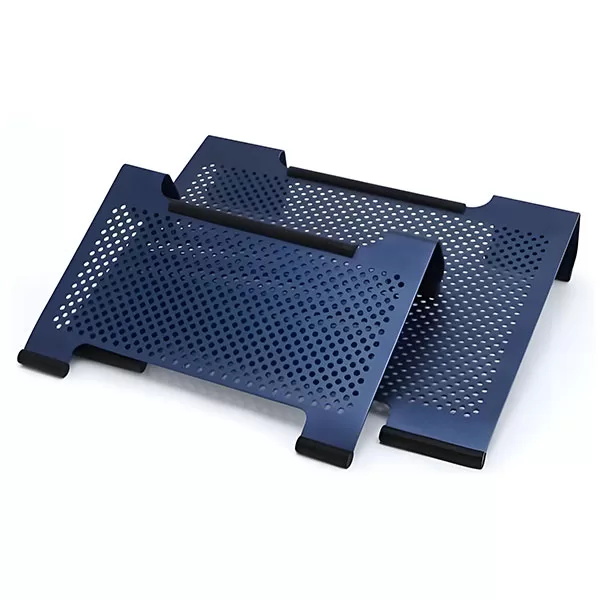

Vacuum Casting Service Surface Finishing

We provide various surface finishing techniques, including polishing, electroplating, painting, and anodizing. Whether to enhance the appearance or improve durability, we offer the best finishing solutions for your project.

Our Vacuum Casting Service Industry Solutions

Tailored Prototyping Services for Every Industry’s Unique Challenges and Needs

Medical Devices

Automotive Industry

Consumer Electronics

Education & Training

Trusted by R&D Groups Worldwide

More than1890 companies from 96 countries trust us, and the number is growing.

Our Clients Success Stories

What Our Clients Say

Client’s trust is the key to our success

★★★★★

Being able to get prototypes so fast has really sped up our development process.

Aaron

★★★★★

The quality of the parts we’ve received has always been top-notch. They really pay attention to the details.

Brandon

★★★★★

Their on-demand manufacturing service makes it easy for us to scale production as needed. It’s incredibly convenient.

William

★★★★★

A lot of professional advice to speed up the progress of my project, great!

Smith