CNC Machining Services Technical Specifications

| Tolerance lever | Size Range | Size Range | Size Range | Size Range | Size Range | Size Range | Size Range |

| Specifications | <<3, >0.5 | <<6, >3 | <<30, >6 | <<120, >30 | <<400, >120 | <<1000, >400 | <<2000, >1000 |

| / | Tolerance standard | Tolerance standard | Tolerance standard | Tolerance standard | Tolerance standard | Tolerance standard | Tolerance standard |

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

Advantages Of CNC Machining Service For Product Developers

- There are many high-performance materials that can be used.

- The products produced have good physical and chemical properties.

- High degree of automation and high production efficiency.

- CNC has strong adaptability to machining objects, thus shortening the production preparation cycle of the product.

- High machining precision and stable quality.

- The machining dimensional precision is between 0.005 and 0.01 mm.High consistency of products.

- The production efficiency is high in the case of multi-variety and small batch production.

- It can process complex profiles that are difficult to process by conventional methods, even some unobservable processing parts.

Advantages Of QDJ-Prototype CNC Machining Service

- More than 80 precision CNC machining centers to ensure output and high precision.

- With the world’s advanced German HERMLE C22, C42 and C62 5-axis CNC machining centers, the workpiece quality can reach 2500 kg, and can produce top turning and milling products.

- More than 12 years of rich experience in the industry.

Have a strong engineering design and project team. - Various complete post-surface treatment processes fully meet product appearance and surface performance requirements.

Have industry-leading testing equipment to ensure the dimensional accuracy of products.

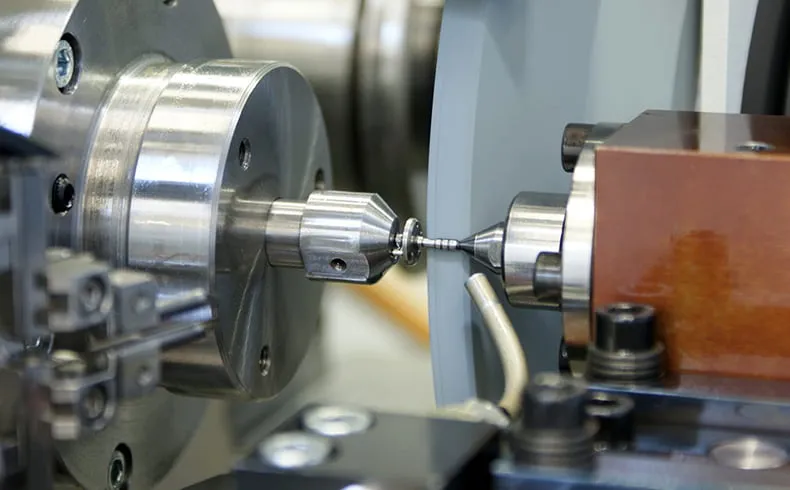

What is CNC machining?

CNC machining is a subtractive manufacturing process in which various precision cutting tools are used to remove raw materials to make a part or product. Advanced software is used to control device specifications according to your 3D design. Our team of engineers and mechanics program the equipment to optimize cutting time, surface finish and final tolerances to meet your specifications

Surface Treatment Of CNC Machining Service

As machined (Ra 3.2μm / Ra 126μin)

This is our standard finish. Parts are machined and deburred, sharp edges are chamfered.

Smooth machining (Ra 1.6μm / Ra 63μin)

–Smooth machining is like an ‘As machined’ finish but slightly less evident machine marks. Parts are machined at a lower feed, and no hand polishing is applied.

Polishing (Ra 0.8μm / Ra 32μin)

–To reduce machining marks, parts are brushed manually with #400 – 600 grit sandpaper. Ideal to slightly reduce the roughness of the finish.

Brushed (Ra 1.2μm / Ra 47μin)

–To reduce machining marks, parts are brushed manually with #400 – 600 grit sandpaper. Ideal to slightly reduce the roughness of the finish.

Powder coated

–Powder coating is a strong, wear-resistant finish compatible with all metal materials.

Bead blasted

–Parts are bead blasted with glass beads, resulting in a grainy texture and reduced machining marks.

Black oxide

–Applicable on steels, black oxide is a conversion coating used to improve corrosion resistance and minimize light reflection.

Electroless Nickel Plating

–Parts are machined to Ra1.6μm and electroless nickel plated. Ideal for wear abrasion and corrosion resistance, not for cosmetic purposes.

As machined + Anodized type III (Hardcoat)

–Parts are machined, and an anodizing type III coating is directly applied to the surface—ideal for improving corrosion and wearing resistance of components.

As machined + Anodized type II

–Parts are anodized (type II) directly after machining. The most cost-effective anodizing option, ideal for non-cosmetic, functional parts. They are used to improve wear and corrosion resistance.

Brushed + Anodized type II (Glossy)

–Parts are manually brushed with fine sandpaper to attenuate the machining marks and then anodized. Ideal for increasing the corrosion resistance of the part. Typically results in a glossy aspect.

Bead blasted + Anodized type II (Matte)

–Parts are bead blasted and anodized type II. Ideal for increasing the corrosion resistance of the part. Results in naturally matte colors. For glossy colors, please select the bead-blasted + glossy anodizing option.

Tumbled

–This is a batch-based process that tumbles vibrating media to remove sharp edges and burrs on machined parts. Tumbling can remove machine marks on exterior surfaces. Parts over 8” may require a manual review.

PTFE I

mpregnated Hard Anodize–A hard coat anodize process that embeds PTFE to create a self-lubricating, dry contact surface with Type 3 hard coat’s protective properties. This finish can be used on aluminum alloys or titanium and increases the service life of the product. This finish conforms to the AMS-2482 Type 1 Hard Coat Anodizing with Teflon (Non-Dyed).

Passivation

–Improves corrosion resistance for 200 and 300 series and precipitation hardened corrosion-resistant steels. Thickness is negligible, about 0.0000001”. Conforms to ASTM A967, AMS-QQ-P-35, MIL-STD-171, ASTM A380, or AMS 2700.

Electropolishing

–An electrochemical process cleans steel parts to reduce corrosion and improve appearance, by making the metal brighter. Removes about 0.0001”-0.0025” of the metal. Conforms to ASTM B912-02.

Silver Plating

–Silver offers high solderability and electrical conductivity but is susceptible to tarnish. Conforms to AMS QQ-S-365D. Thickness is about 0.00002” – 0.0003.”

Gold Plating

–Gold Plating provides good corrosion and tarnish resistance with excellent solderability. Default application specification is MIL-G-45204 and ASTM B488, CLASS 00, 0, OR 1. Thickness is about 0.00002″ – 0.00005.”

Zinc Plating

–Provides uniform zinc coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. Conforms to ASTM B633-15.

Custom Coatings & Finishes

– Available upon your request.

CNC Machining Materials QDJ Use

Metal CNC Machining Materials

| Type | Material | Type | Material |

| Aluminum | Aluminum 6061-T651 | Low Carbon Steel | Low Carbon Steel CR 1008 |

| Aluminum | Aluminum 7075-T651 | Low Carbon Steel | CR Galvanized |

| Aluminum | Aluminum AlSi10Mg | Low Carbon Steel | CR Galvannealed |

| Aluminum | Aluminum 5052-H32 | Stainless Steel | Stainless Steel 17-4 PH |

| Brass | Brass C260 | Stainless Steel | Stainless Steel 304/304L |

| Brass | Brass C360 | Stainless Steel | Stainless Steel 316 |

| Cobalt Chrome | Cobalt Chrome | Stainless Steel | Stainless Steel 316L |

| Copper | Copper C101 | Stainless Steel | Stainless Steel 303 |

| Copper | Copper C100 | Steel Alloy | Steel Alloy 4140 |

| Copper | Copper CuNi2SiCr | Titanium | Titanium Ti 6Al-4V |

| Inconel | Inconel 718 | Titanium | Titanium Grade 5 6A1-4V |

| Low Carbon Steel | Steel CR 1018 |

Plastic CNC Machining Materials

| Type | Material | Type | Material |

| ABS | ABS | PMMA (Acrylic) | PMMA (Acrylic) |

| ABS | ABS Flame Retardant | POM (Acetal/Delrin) | Acetal Homopolymer (Delrin 150) |

| CPVC | CPVC | POM (Acetal/Delrin) | Acetal 20% GF (Delrin 570) |

| HDPE | LDPE | POM (Acetal/Delrin) | Acetal Copolymer |

| LDPE | LDPE | POM (Acetal/Delrin) | Acetal Static Dissipative (Tecaform SD) |

| PA (Nylon) | Nylon 6 Light Blue | PP | PP (Polypropylene Copolymer) |

| PA (Nylon) | Nylon 6/6 | PP | PP (Polypropylene Copolymer) |

| PA (Nylon) | Nylon 6/6 (30% GF)_Natural | PPE/PS | PPE/PS |

| PA (Nylon) | Nylon 6 Black | PPE/PS | Noryl 265 |

| Polycarbonate (PC) | Polycarbonate (20% GF) | PPSU | PPSU |

| Polycarbonate (PC) | Polycarbonate – Black | PPSU | Radel R 5500 |

| Polycarbonate (PC) | Polycarbonate – Clear | PS | PS (HIPS) |

| Polycarbonate (PC) | Polycarbonate – Translucent | PSU | PSU |

| PEEK | PEEK | PTFE (Teflon) | PTFE (Teflon) |

| PEI | Ultem 1000 | PVC | PVC |

| PEI | Ultem 2300 (30% GF) | UHMW | UHMW |

| PET | PET | UHMW | Quadrant EPP Tivar 1000 |

QDJ Follows ISO-2768 Standards For CNC Machining Service

| Limits for nominal size | Metal (ISO2768-m) | Plastic |

| 0.5mm to 3mm | ±0.05mm | ±0.1mm |

| Over 3mm to 6mm | ±0.05mm | ±0.1mm |

| Over 6mm to 30mm | ±0.1mm | ±0.2mm |

| Over 30mm to 120mm | ±0.15mm | ±0.3mm |

| Over 120mm to 400mm | ±0.2mm | ±0.5mm |

| Over 400mm to 1000mm | ±0.3mm | ±0.8mm |

| Over 1000 mm to 2000mm | ±0.5mm | ±1.2mm |

| Over 2000mm to 4000mm | ±2mm |