You Desgin it WE made it

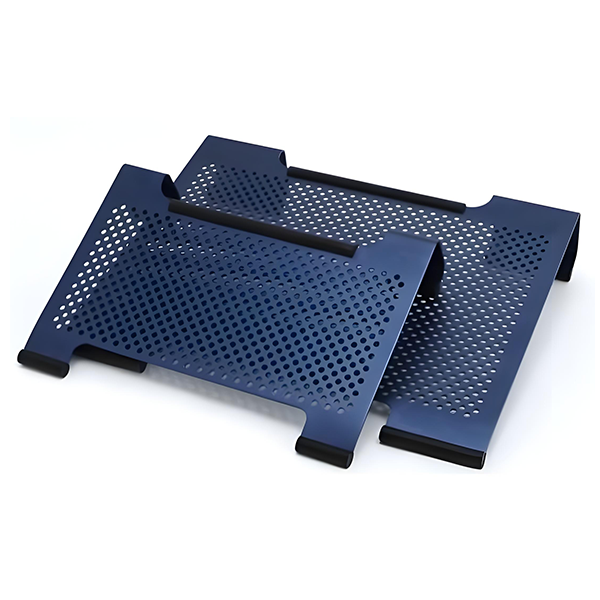

Mold Making Services

Mold Making Service: Quality Molds for Fast and Reliable Production

Why Choose Our Mold Making Services?

Our mold making services are essential for high-volume, precision manufacturing. With our expertise, we deliver molds that are durable, highly accurate, and optimized for efficient production, ensuring cost-effectiveness and consistent quality for your products.

Types of Molds We Specialize In

Our Mold Making Processes

01

Design

Using advanced CAD/CAM technology to create precise mold designs tailored to your specific needs.

02

Material Selection

Choosing the right materials for the mold, ensuring durability and performance during production.

03

Mold Fabrication

High-precision machining processes to build the mold with exact specifications and tight tolerances.

04

Inspection & Testing

Rigorous quality control checks to ensure the mold meets all design and performance criteria.

05

Trial Runs

Conducting trial production runs to verify the mold’s performance before full-scale production.

Mold Making Service Materials

Tool Steel

High-strength, wear-resistant material ideal for long-lasting molds used in high-volume production.

Aluminum

Lightweight and easy to machine, perfect for prototypes and low-volume production molds.

Alloy Steel

Offers a good balance of toughness, machinability, and resistance to wear and tear.

Mold Making Service Surface Finishing

We provide various surface finishing techniques, including polishing, electroplating, painting, and anodizing. Whether to enhance the appearance or improve durability, we offer the best finishing solutions for your project.

Trusted by R&D Groups Worldwide

More than1890 companies from 96 countries trust us, and the number is growing.

Our Clients Success Stories

What Our Clients Say

Client’s trust is the key to our success

★★★★★

Being able to get prototypes so fast has really sped up our development process.

Aaron

★★★★★

The quality of the parts we’ve received has always been top-notch. They really pay attention to the details.

Brandon

★★★★★

Their on-demand manufacturing service makes it easy for us to scale production as needed. It’s incredibly convenient.

William

★★★★★

A lot of professional advice to speed up the progress of my project, great!

Smith