You Desgin it WE made it

Rapid Prototyping Service

Direct Factory Savings: Save 20% by cutting out the middleman.

Fast Quotes: Get a quote within 12 hours.

Quick Delivery: Get your products in as fast as 3 days.

Why Choose Our Rapid Prototyping?

When you’re starting product development, you need fast and accurate prototypes to check your designs, test how things work, and show your ideas to others. Traditional manufacturing methods can be slow and cost a lot of money, but our Rapid Prototyping Service is the perfect solution for you.

At our factory, we know how important your time and budget are. That’s why we focus on delivering fast, reliable prototypes that help you move forward quickly and efficiently. With our Rapid Prototyping Service, you can create the parts you need, stay on schedule, and succeed in a competitive market.

Rapid Prototyping Service Processes

We provide a wide range of Rapid Prototyping Services, including 3D printing, CNC machining, vacuum casting, and injection molding. Each service has its own strengths and is perfect for different steps in product development. Whether you need fast 3D printing for early designs or CNC machining for precise parts, we have the right solution to match your needs. Our goal is to help you choose the best process to speed up your project and bring your ideas to life.

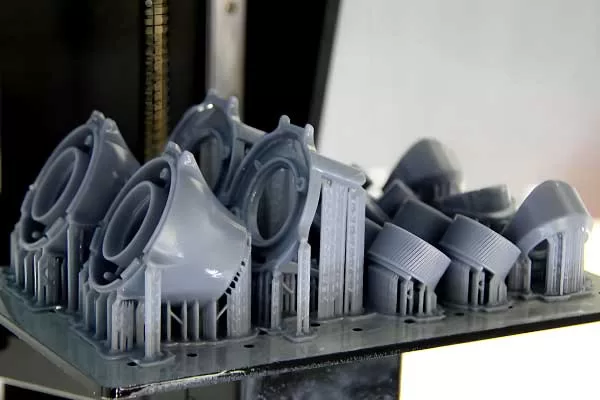

3D Printing

We offer FDM, SLA, and SLS 3D printing services to help you make prototypes quickly and affordably. Our efficient process gives you high-quality results without the high cost. Let us help you bring your ideas to life with our reliable rapid prototyping services!

Learn more

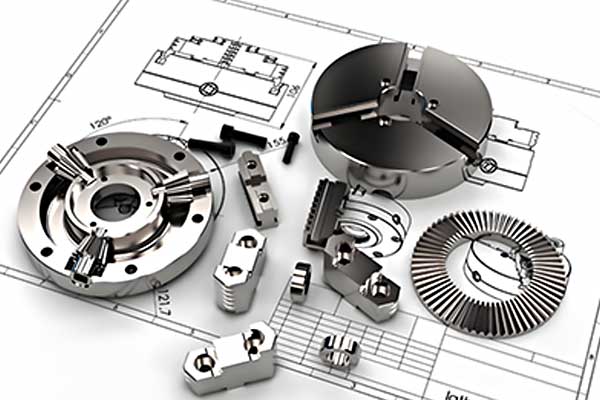

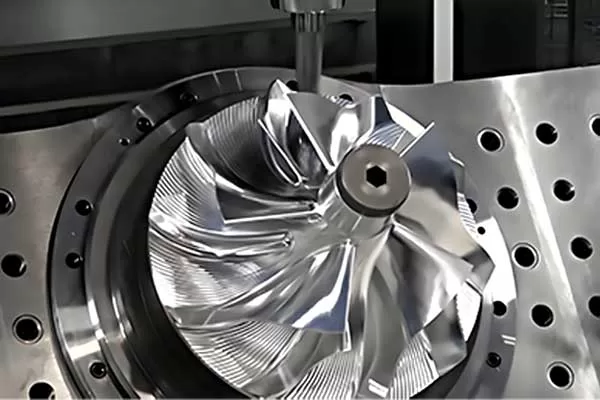

CNC Machining

At our factory, we provide precise CNC machining for metal and plastic parts. This ensures top-quality results every time. Our services are perfect for fast prototyping and small production runs.

Learn more

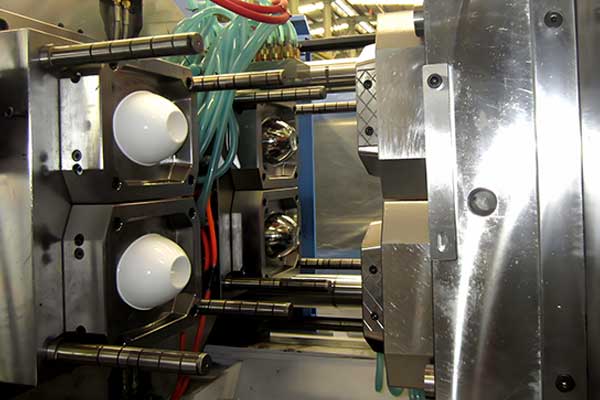

Injection Molding

We provide high-quality injection molding services to quickly and efficiently make a lot of plastic parts. This helps you meet your big production needs for prototypes.

Learn more

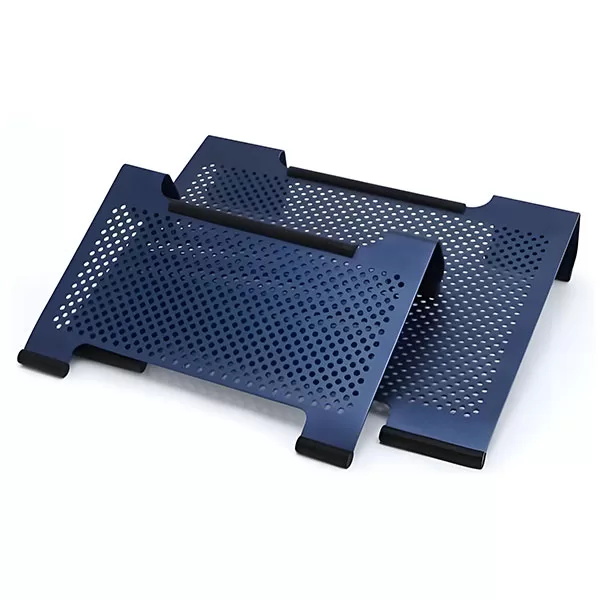

Sheet Metal Fabrication

Our factory provides sheet metal fabrication that is precise, flexible, and efficient. It’s perfect for making high-quality, cost-effective products and custom prototypes while meeting strict tolerance standards.

Learn more

Vacuum Casting

Our Company offers vacuum casting with silicone molds for fast and affordable small-batch production, giving you an advantage over CNC machining and injection molding.

Learn more

Surface Finshing

Our factory provides a complete set of surface finishing services. This includes finishing, painting, and assembly to make sure your products look great and work well. We focus on quality and efficiency, so you can trust us to meet your needs!

Learn moreGet Your Design Realized in 4 Steps

01

Upload a CAD File

Easily upload your 3D CAD file.

02

Quote & Design Analysis

Receive a detailed quote and feedback.

03

Order Confirmed

Confirm your order and start production.

04

Parts are Shipped

Get your parts shipped to your door.

Trusted by R&D Groups Worldwide

More than1890 companies from 96 countries trust us, and the number is growing.

Medical Devices

Automotive Industry

Consumer Electronics

Education & Training

What Sets Our Rapid Prototyping Service Apart?

Direct Factory Savings: Save 20% by cutting out the middleman.

Fast Quotes: Get a quote within 12 hours.

Quick Delivery: Get your products in as fast as 3 days.

Typically, 5 to 10 business days, depending on the complexity. We’ll give you a clear timeline when you request a quote.

Yes, we can help refine your design and guide you through the prototyping process to ensure the best results.

We sign NDAs and follow strict protocols to protect your designs and intellectual property.

Prototyping is for testing and refining new designs, while on-demand manufacturing is for producing small to medium batches of parts quickly.

Pricing depends on the project. We require a deposit to start, with the balance due at completion. We accept various payment methods.

Submit your details online or contact us. We’ll send a quote and guide you on ordering. Get a Quote NOW

Rapid Prototyping Service Materials

We have many material choices like ABS, PLA, nylon, aluminum, titanium alloy, stainless steel, and resin. Pick the best material for your project to make sure your prototype looks great and works well.

Plastic

Here are the plastic materials we often use. We can also work with other materials you need.

Characteristics: Great impact resistance, good heat resistance, performs well in cold, easy to work with, and has a smooth surface.

Applications: Used in car interiors, appliance covers, toys, and electronic cases.

Characteristics: Biodegradable, eco-friendly, melts at a low temperature, and easy to work with.

Applications: Used for 3D printing, packaging, and medical implants.

Characteristics: Strong, wear-resistant, resistant to chemicals, and good at handling stress.

Applications: Used in industrial gears, bearings, machine parts, and fabrics.

Characteristics: High transparency, strong impact resistance, high-temperature resistance, good electrical insulation. Applications: Transparent face shields, safety guards, optical discs, electronic components.

Characteristics: High chemical resistance, low moisture absorption, good impact resistance, lightweight. Applications: Packaging materials, plastic bags, containers, pipes.

Metal

These are the metal materials we often use. We can also work with other materials you need.

Characteristics: Lightweight, corrosion-resistant, good conductivity and thermal conductivity, easy to process. Applications: Aerospace, automotive parts, electronics, construction materials.

Characteristics: Excellent corrosion resistance, high strength, high-temperature resistance, easy to clean. Applications: Cutlery, medical instruments, architectural structures, food processing equipment.

Characteristics: Good conductivity and thermal conductivity, corrosion-resistant, easy to weld. Applications: Electrical wires, electrical components, piping, decorative items.

Characteristics: High strength, corrosion-resistant, lightweight, good biocompatibility. Applications: Aerospace, medical implants, chemical equipment.

Rapid Prototyping Service Surface Finishing

We offer Rapid Prototyping Service with many surface finishing techniques like polishing, electroplating, painting, and anodizing. Whether you want to make your product look better or last longer, we have the best finishing solutions for you.